There is a sealed cavity in the electromagnetic valve for water, which is trepaned with holes at different positions, each of which leads to different oil pipes. There is a valve in the middle of the cavity with two electromagnets on both sides. The valve body will be attracted to either side on which the magnet coil is energized. By controlling the movement of the valve body, different holes will be blocked or exposed to discharge oil. The oil inlet hole is normally open, so hydraulic oil will enter different oil discharge pipes. Then the oil pressure will push the piston of the oil cylinder, which in turn drives the piston rod which drives the machinery. In this way, the mechanical movement is controlled by controlling the current of the electromagnet.

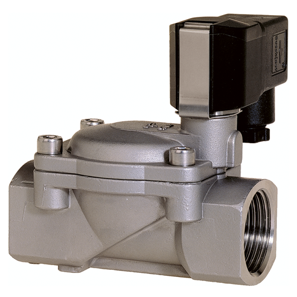

There is a sealed cavity in the electromagnetic valve for water, which is trepaned with holes at different positions, each of which leads to different oil pipes. There is a valve in the middle of the cavity with two electromagnets on both sides. The valve body will be attracted to either side on which the magnet coil is energized. By controlling the movement of the valve body, different holes will be blocked or exposed to discharge oil. The oil inlet hole is normally open, so hydraulic oil will enter different oil discharge pipes. Then the oil pressure will push the piston of the oil cylinder, which in turn drives the piston rod which drives the machinery. In this way, the mechanical movement is controlled by controlling the current of the electromagnet.This valve is a pilot solenoid valve with two-times valve opening mode. Its structure is mainly composed of a pilot valve and a main valve. The main valve adopts rubber sealing structure. In the normal position, the movable iron core seals the pilot valve port, the pressure in the valve cavity is balanced, and the main valve port is closed. When the coil is energized, the electromagnetic force is generated to suck the movable iron core, and the medium in the main valve cavity leaks from the pilot valve port, resulting in a pressure imbalance. The diaphragm or valve cup is shiftly lifted, then the main valve port is opened, and the valve is opened. When the coil is cut off, the magnetic field disappears and the movable iron core is reset. Once the pilot valve port is closed, the pressure in the pilot valve and the main valve chamber is balanced, so the valve is closed again.

Characteristics:

It adopts direct-acting diaphragm structure to start without pressure, which expands its application field.

The flat diaphragm structure is reliable in opening and closing, which also prolongs the service life of the product.

Choosing plastic coil can improve the safe use of this product in various environments.

Specifications:

Model: 2W160-10, 2W160-15, 2W200-20, 2W250-25, 2W350-35, 2W400-40, 2W500-50.

Working medium: air, water and oil.

Action mode: direct action type.

Type: normally closed.

Flow aperture: 16, 20, 25, 35, 40, 50.

CV value: 4.8, 7.6, 12, 24, 29, 48.

Nozzle diameter: 3/8″, 1/2″, 3/4″, 1″, 11/4″, 11/2″, 2″.

Fluid viscosity: below 20CST.

Pressure: Air: 0~1.0Mpa, Water: 0~0.7Mpa, Oil: 0~0.7Mpa.

Maximum pressure resistance: 1.0Mpa (normally opened: 0.8Mpa).

Working temperature: NBR: -5~80℃, EPDM: -5~120℃, VITON: -10~150℃.

Voltage range: ±10%.

Body material: brass.

Oil seal material: NBR, EPDM, VITON.