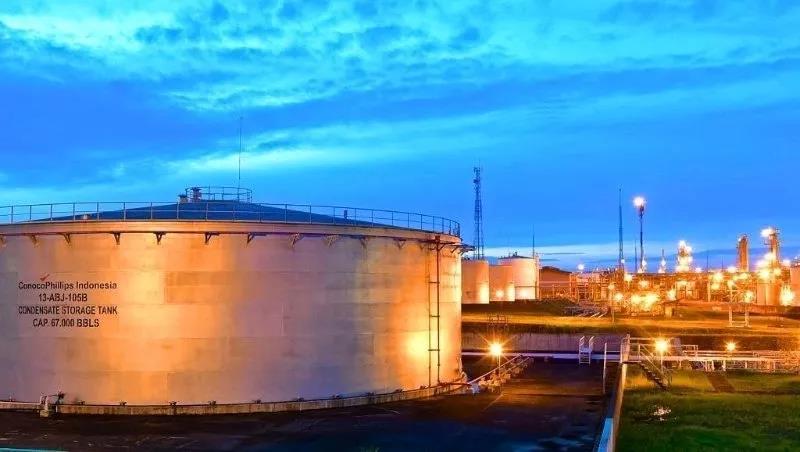

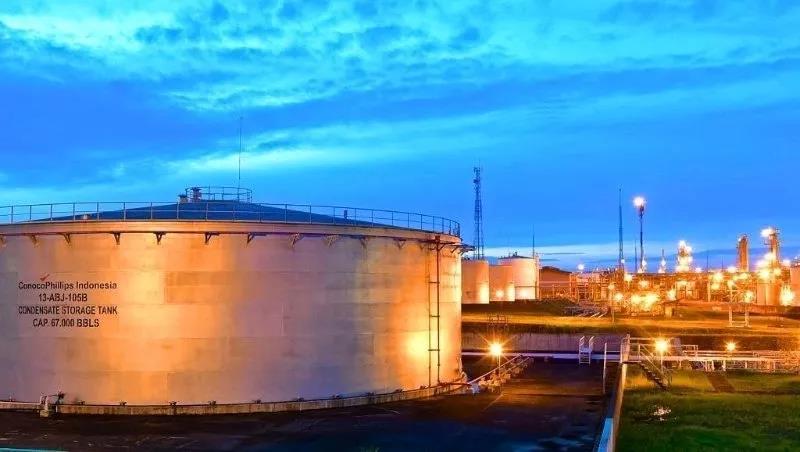

Petrochemical refers to the production of gasoline, kerosene, diesel, lubricating oil and liquefied petroleum gas and other petroleum products using petroleum and natural gas as raw materials; the modern industry that produces olefins and aromatic hydrocarbons by using light oil as raw materials and then produces synthetic resins, synthetic fibers, synthetic rubber, and various chemical raw materials.

The petrochemical industry includes oil refineries, ethylene plants, chemical fiber plants, chemical plants, fertilizer plants, etc., and now many large-scale joint enterprises have become integrated oil refining and chemical plants. The refinery production equipment is divided into primary processing, secondary processing, tertiary processing equipment and auxiliary production equipment.

The primary processing device uses physical straight distillation to process crude oil. The product obtained is called straight straight-run product, and the device used is an atmospheric and vacuum distillation device.

The secondary processing device uses the processed products for reprocessing, which is a physical-chemical process. The purpose is to increase the yield of light hydrocarbons, improve product quality, increase oil varieties, and improve the economic efficiency of refineries. The devices used include catalytic cracking, hydrofinishing, hydrocracking, delayed coking, and lubricating oil production devices.

Ethylene plant: In the production plant of petrochemical plant, ethylene cracking is a leading device. Downstream devices include resin series such as polyethylene, polypropylene, polyvinyl chloride, polystyrene, and ABS; chemical fiber series include polyester, acrylic, vinylon, and nylon.

Petrochemical valves are the most equipment in petrochemical production equipment. All kinds of gas and liquid media in petrochemical production must pass through various valves and be blocked or transported to various containers and process equipment according to the production process. The valves commonly used in petrochemical production are divided into general valves and special valves. The general valves of petrochemical include gate valves, globe valves, ball valves, check valves, butterfly valves, pressure relief valves, safety valves, regulating valves, etc. The petrochemical special valves include the spool valve and high temperature butterfly valve in the catalytic cracking device, the four-way switching valve and the coking valve in the delayed coking device, the high temperature cracking flat gate valve and low temperature valve in the ethylene cracking device solid valves in polyethylene and polypropylene devices, high temperature and high pressure angle type globe valves and throttle valves in synthetic ammonia devices.

Petrochemical general valve:

Domestic valve manufacturing industry is all over the country, and there are 1,300 general valve manufacturers. China has become one of the countries with the largest valve output and market demand in the world. However, most of the valve industry in China is small and medium-sized, and the quality is uneven. Only a dozen of them have an annual output value of more than 100 million yuan. Even compared with other domestic machinery industries, there is still a big gap in terms of installation and technical level. There are few units that truly have the ability to independently research and develop high-end products. National valve product specifications and models have reached more than 40,000, most of which have been standardized and serialized, and some can already be produced in accordance with international standards. The maximum service temperature of the valve has reached 570 ℃, the minimum temperature has reached -196 ℃, the maximum pressure has reached 600MPa, and the maximum diameter has reached 5350mm.

General valves basically meet most of the needs of petrochemical production, while, as for special valves such as safety valves, globe valves, check valves and others, due to the lack of sealing materials, improper matching of sealing materials, and that the heat treatment process cannot meet the requirements, the performance and service life are affected. Automatic valves, such as safety valves, pressure reducing valves, and traps, lack experimental research methods, and some products have unstable performance. Due to the lack of test methods, control valves such as butterfly valves and throttle valves generally do not have adjustment characteristic curves and resistance coefficient curves. The control level of the electric actuator is low, the control is not effective, and the accuracy is not high.

The technical level of foreign general valves is relatively high and the development speed is fast, mainly manifested in: the valve is developing in the direction of large-scale, high parameterization, automation and complete sets, the product series is continuously increasing, the quality of new valve products is high, the seal is reliable, and the life is long; The valve research is specialized and has a scientific research and testing base, which can carry out various tests such as thermal performance, dynamic performance, wear resistance, seismic resistance, fire resistance, reliability, etc., and can perform various performance tests on products.

With the development of petrochemical industry and the requirements of technological progress, the demand for high-parameter general-purpose valves has increased. For example, the operating temperature of high-temperature valves reaches 500 - 900 ℃; the operating temperature of low-temperature valves reaches -40 - -190 ℃; the operating pressure of high-pressure valves reaches 300 - 500Mpa; especially for flammable, explosive, strongly corrosive, and toxic media, , higher and stricter requirements have been put forward on the safety, functional reliability, and service life of valves.

In the selection of valve materials and manufacturing processes, the requirements for use must be first met, improving the safety and reliability of the valve, and we should pay attention to its economic benefits. In recent years, many new high-performance materials have emerged, such as various metal materials like strong corrosion-resistant titanium and zirconium, inorganic non-metallic materials and various composite materials like nano materials, organic synthetic and polymer materials, industrial ceramics. At the same time, many new processes and new technology equipment such as casting, welding, spray welding, spraying, compounding, sintering and other molding and surface treatments are emerging, which are being applied to valve production.

In order to adapt to the development of information technology, the valve, as the terminal actuator for controlling the movement of fluid in the pipeline, is applying modern computing technology, sensing technology, network and remote control technology, and intelligent technology to valve products, especially regulating valves, pressure reducing valves and safety valves.

The petrochemical industry includes oil refineries, ethylene plants, chemical fiber plants, chemical plants, fertilizer plants, etc., and now many large-scale joint enterprises have become integrated oil refining and chemical plants. The refinery production equipment is divided into primary processing, secondary processing, tertiary processing equipment and auxiliary production equipment.

The primary processing device uses physical straight distillation to process crude oil. The product obtained is called straight straight-run product, and the device used is an atmospheric and vacuum distillation device.

The secondary processing device uses the processed products for reprocessing, which is a physical-chemical process. The purpose is to increase the yield of light hydrocarbons, improve product quality, increase oil varieties, and improve the economic efficiency of refineries. The devices used include catalytic cracking, hydrofinishing, hydrocracking, delayed coking, and lubricating oil production devices.

Ethylene plant: In the production plant of petrochemical plant, ethylene cracking is a leading device. Downstream devices include resin series such as polyethylene, polypropylene, polyvinyl chloride, polystyrene, and ABS; chemical fiber series include polyester, acrylic, vinylon, and nylon.

Petrochemical valves are the most equipment in petrochemical production equipment. All kinds of gas and liquid media in petrochemical production must pass through various valves and be blocked or transported to various containers and process equipment according to the production process. The valves commonly used in petrochemical production are divided into general valves and special valves. The general valves of petrochemical include gate valves, globe valves, ball valves, check valves, butterfly valves, pressure relief valves, safety valves, regulating valves, etc. The petrochemical special valves include the spool valve and high temperature butterfly valve in the catalytic cracking device, the four-way switching valve and the coking valve in the delayed coking device, the high temperature cracking flat gate valve and low temperature valve in the ethylene cracking device solid valves in polyethylene and polypropylene devices, high temperature and high pressure angle type globe valves and throttle valves in synthetic ammonia devices.

Petrochemical general valve:

Domestic valve manufacturing industry is all over the country, and there are 1,300 general valve manufacturers. China has become one of the countries with the largest valve output and market demand in the world. However, most of the valve industry in China is small and medium-sized, and the quality is uneven. Only a dozen of them have an annual output value of more than 100 million yuan. Even compared with other domestic machinery industries, there is still a big gap in terms of installation and technical level. There are few units that truly have the ability to independently research and develop high-end products. National valve product specifications and models have reached more than 40,000, most of which have been standardized and serialized, and some can already be produced in accordance with international standards. The maximum service temperature of the valve has reached 570 ℃, the minimum temperature has reached -196 ℃, the maximum pressure has reached 600MPa, and the maximum diameter has reached 5350mm.

General valves basically meet most of the needs of petrochemical production, while, as for special valves such as safety valves, globe valves, check valves and others, due to the lack of sealing materials, improper matching of sealing materials, and that the heat treatment process cannot meet the requirements, the performance and service life are affected. Automatic valves, such as safety valves, pressure reducing valves, and traps, lack experimental research methods, and some products have unstable performance. Due to the lack of test methods, control valves such as butterfly valves and throttle valves generally do not have adjustment characteristic curves and resistance coefficient curves. The control level of the electric actuator is low, the control is not effective, and the accuracy is not high.

The technical level of foreign general valves is relatively high and the development speed is fast, mainly manifested in: the valve is developing in the direction of large-scale, high parameterization, automation and complete sets, the product series is continuously increasing, the quality of new valve products is high, the seal is reliable, and the life is long; The valve research is specialized and has a scientific research and testing base, which can carry out various tests such as thermal performance, dynamic performance, wear resistance, seismic resistance, fire resistance, reliability, etc., and can perform various performance tests on products.

With the development of petrochemical industry and the requirements of technological progress, the demand for high-parameter general-purpose valves has increased. For example, the operating temperature of high-temperature valves reaches 500 - 900 ℃; the operating temperature of low-temperature valves reaches -40 - -190 ℃; the operating pressure of high-pressure valves reaches 300 - 500Mpa; especially for flammable, explosive, strongly corrosive, and toxic media, , higher and stricter requirements have been put forward on the safety, functional reliability, and service life of valves.

In the selection of valve materials and manufacturing processes, the requirements for use must be first met, improving the safety and reliability of the valve, and we should pay attention to its economic benefits. In recent years, many new high-performance materials have emerged, such as various metal materials like strong corrosion-resistant titanium and zirconium, inorganic non-metallic materials and various composite materials like nano materials, organic synthetic and polymer materials, industrial ceramics. At the same time, many new processes and new technology equipment such as casting, welding, spray welding, spraying, compounding, sintering and other molding and surface treatments are emerging, which are being applied to valve production.

In order to adapt to the development of information technology, the valve, as the terminal actuator for controlling the movement of fluid in the pipeline, is applying modern computing technology, sensing technology, network and remote control technology, and intelligent technology to valve products, especially regulating valves, pressure reducing valves and safety valves.