In modern industry and infrastructure construction, steel pipes play an irreplaceable role as important materials for conveying media, bearing structures, and protective devices. Welded steel pipes, due to their flexible manufacturing processes, reliable performance, and moderate cost, have become the most widely used type of pipe in various engineering projects. With the diversification of engineering requirements and the continuous improvement of technical standards, the performance differences and applicable ranges of different types of welded steel pipes have become important considerations for engineering design, procurement, and construction. This article starts with the basic classification of welded steel pipes and systematically introduces the process characteristics, mechanical properties, application fields, and selection strategies of longitudinally welded pipes and spiral welded pipes, helping readers fully understand the technical features and practical value of welded steel pipes.

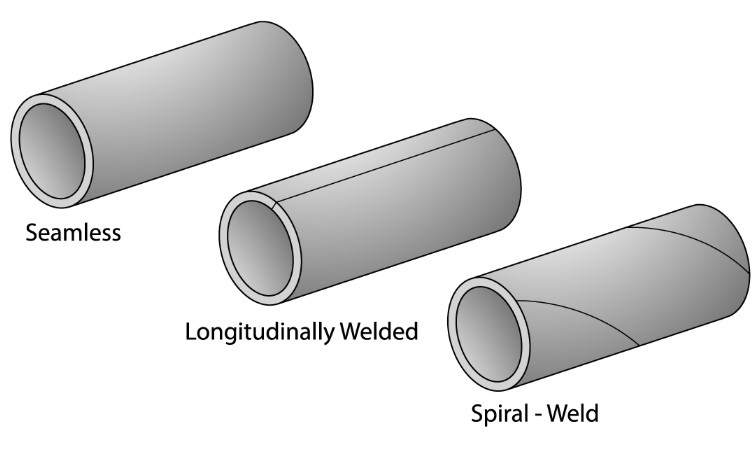

Welded steel pipes are mainly divided into two categories according to the type of weld: longitudinally welded pipes and spiral welded pipes. Although both belong to the category of welded steel pipes, there are obvious differences in production processes, performance characteristics, and application fields. Understanding these differences is of great significance for engineering material selection and procurement decisions.

The weld of a longitudinally welded pipe is parallel to the pipe axis, and the production process is relatively simple. The weld of a spiral welded pipe is distributed in a spiral shape and is manufactured using a continuous bending forming process. Each type of steel pipe has its own advantages and is suitable for different engineering scenarios.

Spiral seam submerged arc welded steel pipes, usually referred to as spiral welded pipes, spiral pipes, or spiral steel pipes, are made by bending hot-rolled steel strips into a spiral shape and then welding both the inner and outer seams using automatic submerged arc welding. This unique forming method gives spiral welded pipes many advantages that longitudinally welded pipes do not have.

Spiral welded pipes can be widely used in the production of large-diameter steel pipes, mainly based on the following four reasons:

High production flexibility: By simply changing the forming angle, pipes of various diameters can be produced from the same strip width. This means manufacturers do not need to prepare multiple widths of raw materials, greatly reducing inventory costs and production complexity.

Unlimited length: Due to the continuous bending forming process, the fixed-length of steel pipes can be adjusted arbitrarily according to engineering needs, unlike longitudinal welded pipes which are limited by plate length.

High dimensional accuracy and strength: The spiral distribution of the weld seam around the entire pipe circumference ensures higher dimensional accuracy and overall strength.

Suitable for small-batch, multi-spec production: When engineering projects require multiple specifications of steel pipes, spiral welded pipe production lines can quickly adjust parameters and flexibly change sizes to meet personalized requirements.

From the perspective of usage performance, spiral welded pipes have unique advantages. Since defects are parallel to the weld seam, the weld seam defects of spiral pipes manifest as oblique defects. During use, the main stress direction of the steel pipe is along the axial direction, at which point the equivalent defect length of the spiral weld is smaller than that of longitudinally welded pipes.

More importantly, pipeline steel materials themselves exhibit anisotropic characteristics. During rolling, the impact toughness (CVN value) in the rolling direction can be three times higher than that perpendicular to the rolling direction. The main stress direction of longitudinal welded pipes is precisely perpendicular to the pipe's lowest impact resistance direction, whereas spiral pipes avoid this weak direction, turning the disadvantage of a longer weld seam into an advantage.

Longitudinally welded steel pipes have weld seams parallel to the pipe axis and are usually divided into metric electric welded pipes, electric welded thin-walled pipes, transformer cooling oil pipes, and other types. Compared with spiral welded pipes, longitudinally welded pipes have a simpler and more direct production process.

Longitudinally welded pipes can be divided into two major categories according to the production process: high-frequency longitudinal welded pipes and submerged arc longitudinal welded pipes (LSAW).

High-frequency longitudinal welded pipes adopt high-frequency resistance welding technology, with high production efficiency, suitable for mass production of medium and small-diameter pipes.

Submerged arc longitudinal welded pipes (LSAW) use submerged arc welding technology with filler materials and granular protective flux. The diameter of pipes produced can reach 1,500 millimeters, with main forming technologies including JCOE forming technology and rolled forming submerged arc welding.

For the production of large-diameter LSAW pipes, the steel plates entering the production line must undergo the following strict procedures:

Full-plate ultrasonic inspection to ensure the raw material is defect-free.

Milling both edges of the steel plate to meet requirements for plate width, edge parallelism, and groove shape.

Pre-bending the edges to achieve the required curvature.

On the JCO forming machine, pre-bent plates are first pressed into a "J" shape, then into a "C" shape, and finally into an open "O" shape.

After forming, continuous welding is performed using gas-shielded welding, followed by multi-wire submerged arc welding on both the inner and outer sides.

After welding, 100% inspection of the weld and base metal on both sides is conducted, including X-ray industrial television inspection.

Pipe expansion improves dimensional accuracy and internal stress distribution.

Finally, the pipe undergoes hydrostatic testing, end processing, and repeated ultrasonic inspection. Qualified products are treated with anti-corrosion and coatings according to user requirements.

In actual engineering material selection, the performance differences between spiral and longitudinal welded pipes are mainly reflected in four dimensions: strength performance, residual stress, quality control, and geometric accuracy. These differences directly determine the applicable scenarios and engineering value of the two types of pipes.

The strength of spiral welded pipes is generally higher than that of longitudinal welded pipes. Narrower billets can produce larger-diameter spiral pipes, and pipes of different diameters can be produced from billets of the same width. This material utilization advantage makes spiral welded pipes cost-competitive in large-diameter applications.

However, compared with longitudinal welded pipes of the same length, the weld seam length of spiral pipes increases by 30% to 100%, resulting in relatively lower production speed. Therefore, longitudinal welding is mostly used for small-diameter pipes, while spiral welding is preferred for large-diameter pipes.

There are significant differences in residual stress. Spiral welded pipe manufacturing leads to higher residual stress, sometimes close to the yield limit. In contrast, LSAW pipes, due to the expansion process, have nearly zero residual stress, which is advantageous for applications requiring high dimensional stability.

In weld inspection, tracking and ultrasonic online testing of spiral welds are more difficult, leading to a higher probability of weld defects exceeding standards. In addition, the misalignment of spiral pipe welds is mostly 1.1–1.2 mm. According to international practice, misalignment should be less than 10% of the thickness. For thin walls, spiral pipes may not meet this requirement, whereas LSAW pipes do not have this problem.

The heat-affected zone of spiral submerged arc welded pipes is larger than that of LSAW pipes, and the heat-affected zone is a weak link in pipe quality. Meanwhile, the geometric dimensional accuracy of spiral welded pipes is relatively lower, posing certain difficulties in field assembly and welding. For the same diameter, the maximum thickness achievable by spiral welded pipes is far less than that of LSAW pipes.

In actual material selection, it is not simply a matter of which type is better. Selection should be based on usage conditions, pressure requirements, diameter, construction environment, and other factors. Understanding the characteristics of these two types of pipes ensures they are applied appropriately.

General welded pipes, commonly called black pipes, are mainly used for transporting water, gas, air, oil, and low-pressure steam. They are made from Q195, Q215A, Q235A, Q235B carbon steel, or weldable 0317 standard model 6012 and steel billet 755 mild steel.

Pipes must undergo hydrostatic, bending, and flattening tests, with certain requirements for surface quality. Typical delivery lengths are 4–10 meters, with fixed-length or multiple-length deliveries. Pipe specifications are expressed as nominal diameter (mm or inch), which does not exactly equal the actual inner diameter. According to wall thickness, there are ordinary and thickened pipes, and according to pipe ends, threaded and non-threaded types exist.

Low-pressure galvanized welded steel pipes, commonly called white pipes, are heat-dip galvanized versions of black pipes, offering better corrosion resistance for applications requiring durability.

Spiral seam submerged arc welded pipes: Made from hot-rolled steel coils, formed spirally at room temperature, and welded with double-sided submerged arc welding. These pipes have strong pressure resistance, good weldability, and reliable safety after strict inspections and tests. Large diameter allows high transport efficiency, saving pipeline investment, mainly for petroleum and natural gas pipelines.

Spiral seam high-frequency welded pipes: Also formed from hot-rolled steel coils and spirally shaped at room temperature, but welded with high-frequency overlap welding. These pipes have good plasticity, easy to weld and process, mainly used in petroleum and natural gas transport pipelines.

Ordinary carbon steel conduit pipes protect electrical wires in industrial and civil installations, belonging to a specialized application of longitudinal welded pipes.

Spiral seam pile pipes are used for civil building structures, docks, bridges, etc., produced by double-sided submerged arc welding or high-frequency welding, designed to bear large axial and lateral loads.

Transformer oil pipes are longitudinally welded pipes applied in power equipment, with strict requirements for dimensional accuracy and cleanliness.

After understanding the specific applications of various welded steel pipes, the next key question is how to make the optimal choice among a wide range of products. Selection affects not only project quality and safety but also cost and construction efficiency. Correct selection requires comprehensively considering diameter, pressure, environment, construction, and other factors to accurately match technical characteristics with practical needs.

Generally, for small-diameter pipes (typically <400 mm), longitudinal welded pipes are recommended due to high production efficiency, low cost, and dimensional accuracy. For large-diameter pipes (>400 mm), spiral welded pipes are recommended because they can produce large-diameter pipes from narrow billets, offer high material utilization, and are not limited in length.

For low-pressure fluid transport (e.g., water, gas, air), general or low-pressure pipes suffice. For medium- and high-pressure applications (e.g., petroleum, natural gas), spiral seam submerged arc welded pipes or high-frequency welded pipes should be used, as these undergo strict quality control and pressure testing.

In corrosive environments, galvanized or specially coated pipes should be used. For piles or special applications, pile-grade spiral welded pipes are required. For electrical installations, standard-compliant carbon steel conduit pipes are recommended.

For ease of on-site construction, longitudinal welded pipes, with high geometric precision, allow easier alignment and welding. Spiral pipes, while slightly less precise, offer flexible lengths that reduce field weld joints, which is also a factor to consider.

Welded steel pipes, as important materials in modern industry and infrastructure construction, come in many types with diverse performance characteristics. Longitudinally welded pipes, with simple production, high efficiency, low cost, and dimensional precision, dominate the small- and medium-diameter field. Spiral welded pipes, with high strength, high material utilization, and flexible length, are indispensable in large-diameter and high-pressure transport.

In actual engineering applications, the characteristics of both pipe types should be comprehensively considered based on diameter, pressure, environment, and construction conditions to select the most suitable product type. Regardless of the chosen type, attention should be paid to manufacturer quality control systems and product certification to ensure the procurement of high-quality, standard-compliant pipes.

With continuous technological advancement and increasingly diverse application needs, welded steel pipe products will continue to be optimized, providing reliable material support for energy transport, urban construction, and industrial development. Understanding these fundamentals helps engineers, procurement personnel, and related enterprises make more scientific and economical decisions, promoting the healthy development of the industry.