Abstract: Valves are essential fluid control components in chemical plants and play a critical role in the overall operation of the system. Designing valves to suit specific operating conditions can greatly improve operational efficiency and extend service life. This article offers a concise overview of valve operating characteristics in sulfur recovery units, focusing on tail gas recovery valves, and systematically discusses valve type selection, structural design, and material selection for critical components. The article analyzes the working principle, valve body design calculations, valve stem design verification, and steam-tracing design validation. The paper also presents practical experience in designing butterfly valves for sulfur recovery units and emphasizes key design considerations for these operating conditions. This discussion provides a valuable reference for the development and design of valves under similar or comparable operating conditions.

Sulfur recovery commonly utilizes the Claus process to extract sulfur from acidic gas streams that contain hydrogen sulfide. In this process, roughly one-third of the hydrogen sulfide is converted into sulfur dioxide through combustion, followed by sulfur recovery through catalytic reactions and condensation. When the process medium flows through a valve, internal condensation and accumulation may occur, potentially leading to problems such as internal leakage, difficulty in operation, or even valve failure, thereby impacting the overall performance of the unit. Therefore, valves used in sulfur recovery units must be designed to address internal heat loss, medium solidification, internal corrosion, and critical shut-off requirements. Based on this context and recent industry developments, this paper provides a concise description of the structural design of a triple-eccentric butterfly valve with an insulated jacket, as applied in sulfur recovery units. It offers design guidance for valve structures under similar operating conditions in other sulfur recovery units, using a typical sulfur recovery unit from a domestic chemical enterprise as a reference, with relevant operating parameters shown in Table 1.

The triple-eccentric jacketed butterfly valve comprises a triple-eccentric butterfly valve body integrated with an external jacket system. The valve body features a triple-eccentric sealing pair that regulates medium cutoff and controls flow within the channel. The jacket system comprises a steel layer surrounding the outer contour of the valve body’s flow channel, forming a separate space independent of the process medium, with external ports strategically positioned on the jacket. During operation, a medium—such as steam or oil—is introduced through one port and exits through another, creating a continuous circulation within the jacket system. This setup transfers heat from the valve body wall to the process medium, ensuring the medium temperature remains within the required range. Figure 1 illustrates the valve’s field application. The triple-eccentric butterfly valve leverages well-established manufacturing techniques and offers cost-effective production. Its frictionless operation and torque-assisted sealing ensure reliable valve seat performance and prolonged service life, while the fully insulated, steam-heated jacket provides uniform fluid heating, preventing medium solidification or crystallization. The primary structural components of the triple-eccentric insulated jacketed butterfly valve are shown in Figure 2.

Table 1 Operating Parameters

|

Tail Gas to Tail Gas Reheater |

Parameter |

|

Medium |

Tail Gas |

|

Valve Body Material |

WCB + NACE |

|

Valve Core Material |

316SS |

|

Valve Stem Material |

17-4PH |

|

Operating Temperature |

155 °C |

|

Closing Pressure Differential |

0.35 MPa |

|

Leakage Class |

Class MI |

|

Nominal Diameter |

DN500 |

|

Nominal Pressure |

Class 150 |

Figure 1 Triple-Eccentric Insulated Jacketed Butterfly Valve

Figure 2 Triple-Eccentric Insulated Jacketed Butterfly Valve Body Structure

The main valve body uses an integral casting structure. The flow space is created by the sealed connection of the rolled plate between the main body and the flange. Flange interfaces are installed on both sides of the jacket to facilitate heat preservation and the heating of inlet and outlet fluids. Additionally, a drain port is provided at the lower end of the valve jacket.

(1) Valve Body Wall Thickness Design

The wall thickness of the valve body is a critical safety parameter and must be carefully determined in accordance with applicable standards. Currently, variations in calculation methods and system approaches lead to multiple ways of determining valve body wall thickness, which can produce differing results. Therefore, the triple-eccentric insulated jacketed butterfly valve follows a widely recognized industry standard. The main body wall thickness is calculated using the minimum wall thickness formula specified in ASME B16.34 Mandatory Appendix VI, with the understanding that this value represents the minimum required thickness. In practice, additional factors, such as corrosion allowance, must be fully taken into account. Because the steam-flange heat tracing structure affects the effective valve diameter (increasing it to DN600), the design follows the inner diameter guidelines in Section 6.1.2 of ASME B16.34 and the flow channel inner diameter ddd specified in the standard. The calculated wall thickness corresponds to DN500, giving a minimum thickness of 0.0163×500+4.7=12.85, rounded to 12.9 mm. Considering additional design factors, the final valve body wall thickness is set at 16 mm.

(2) Pipe Flange Design

The pipe flange connection dimensions are based on HG/T 20592–20635 standards for steel pipe flanges, gaskets, and fasteners, with flange dimensions referenced from ISO 5752. Due to the diameter variation—where the flow channel and internal components have a nominal diameter of DN500, while the valve body flange connection is DN600—the flange thickness and outer diameter are considerably larger than standard nominal dimensions. The installation space for flange bolts must be carefully accounted for, ensuring that wrench clearance, axial bolts, and gasket dimensions of the flow channel meet or exceed the countersunk hole specifications outlined in GB/T 152.4. Additionally, the support plate must extend beyond the flange outer diameter to prevent interference during on-site installation of the pipe flange and valve.

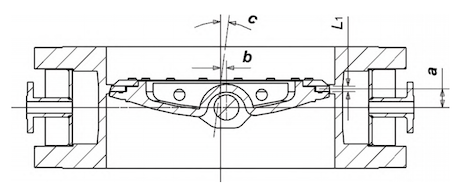

(3) Triple-Eccentric Structure Design

The triple-eccentric design provides frictionless, contactless sealing during valve operation, with the sealing force transmitted via torque. The triple-eccentric sealing arrangement is shown in Figure 3. The first eccentricity, a, represents the offset of the valve stem center from the sealing surface center. The second eccentricity, b, represents the offset of the valve stem center from the valve body (flow channel) center, while the third eccentricity, c, represents the angular offset between the centerline of the sealing surface and the centerline of the valve body (flow channel). Since design practices vary among valve manufacturers, appropriate values may be selected based on actual conditions, taking into account factors such as manufacturing capability, cost, and standardization. In practical applications, selecting appropriate parameters ensures valve safety under operating conditions while also helping to optimize manufacturing costs.

Figure 3 Triple-Eccentric Structure Diagram

For the operating parameters considered in this study, the primary design focus is the valve’s shut-off capability rather than precise flow capacity. This involves analyzing how the three eccentricities influence the operating torque. The second eccentricity b should be kept as small as possible, the first eccentricity a should be appropriately increased, and the third eccentricity c should be selected to reduce driving torque. This allows the use of a smaller actuator and lowers the risk of valve stem failure. Based on the actual operating pressure differential and the “triple-eccentric size calculation method,” the sealing surface width L₁ is 8 mm, and the selected triple-eccentric dimensions are a = 40 mm, b = 8 mm, and c = 7 mm. CAD simulations or other verification methods are then used to confirm the dimensions of the triple-eccentric structure.

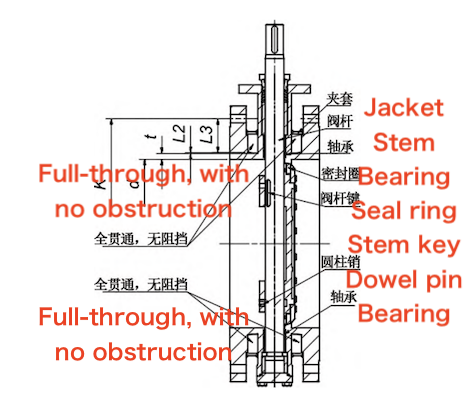

(4) Valve Stem Design

Among all valve body components, the valve stem is especially prone to breakage or significant deformation, which can result in valve failure and even serious safety incidents. As a critical torque-transmitting component, the stem’s structural design, material selection, and verification calculations are essential. Considering the risk of medium solidification and crystallization, the stem diameter must provide sufficient strength to withstand the torque required for valve operation. Verification is carried out in accordance with Table 5-216 of the Practical Valve Design Manual, Third Edition. The stem of the eccentric butterfly valve is evaluated by calculating the total operating torque, after which the appropriate actuator is selected using empirical coefficients. The stem adopts an integral structure, featuring keyed connections to both the actuator and the valve plate, with a locking pin for added security. This configuration maximizes overall structural strength. Critical sections and key-pin strength are verified according to standard references, and the keyway is precisely machined to ensure it does not compromise the stem’s overall performance. Due to the corrosive nature of the medium, the valve stem is made from high-strength, precipitation-hardening stainless steel 17-4PH.

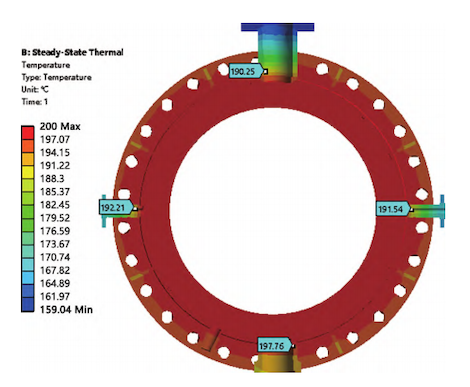

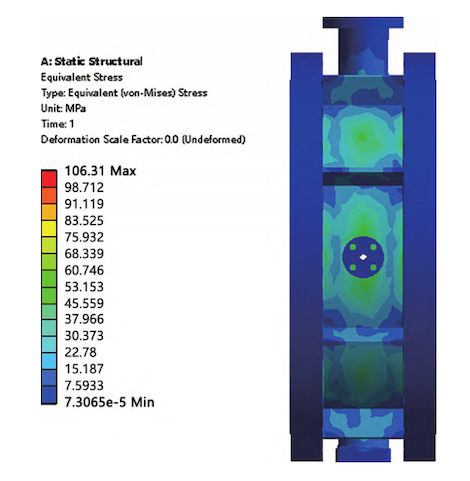

(5) Valve Body Shell Design

The valve body shell is an integral casting. The outer steam jacket is constructed by welding steel coils, with steam inlet and outlet ports on both sides of the jacket, and standard-size flanges installed at each interface. A drain port is positioned near the lower end of the valve stem within the jacket. Multiple stiffening plates are welded between the flanges on both sides of the cast shell to reinforce the structural strength of the main body. The coil and the main body are fully integrated, forming a continuous, rigid structure. Except for the essential stuffing box and end cap, which create unavoidable obstructions at the main body connection, no additional reinforcing stiffening plates are installed within the flow path, minimizing flow interference. The upper and lower bearings are completely enclosed within the insulated jacket, ensuring uniform fluid heating, as illustrated in Figure 4. This design ensures that the temperature around the bearings remains above the sulfur crystallization point. A CAE analysis of the temperature field around the bearing and jacket (Figure 5) shows that, with an input temperature of 200 °C, the bearing temperature is maintained above 190 °C. Because of the jacket design, the valve body flange diameter is altered. To maintain adequate flow space and effective insulation, the nominal inner and outer dimensions of the jacket pipe typically span one to two sizes. For this project, the valve steps up from DN500 to DN600. A rolled-plate jacket is used to ensure manufacturability while satisfying the on-site steam medium’s temperature and corrosion-resistance requirements. As shown in Table 2, although the flange thickness increases due to the diameter change, the lever arm under the tension of the flange bolts on both sides of the valve increases by 2.22 mm. The increase in bolt diameters can reduce flange rigidity, potentially causing leakage at the flange sealing surface during long-term operation. Reinforcing ribs are thus strategically placed within the available space to enhance flange rigidity, prevent deformation from pipeline vibrations, and minimize the risk of cracking caused by rolled plate jacket deformation. Adequate wrench clearance is provided to ensure that the fastener installation surfaces meet or exceed the required countersunk hole dimensions. During valve operation, the jacket is designed to meet strength requirements under steam pressure, typically considering a steam temperature of 200 °C and a pressure of 1 MPa. Professional analysis software is employed to verify the structural integrity of the rolled plate and flange rigidity. Figure 6 shows a stress analysis cloud map of the valve flange and jacket under the specified operating conditions, confirming that the design satisfies strength requirements. The nominal pressure and diameter of the connecting pipe should comply with site-specific thermal requirements, and the interface can be designed as either a flange or threaded connection according to project needs. The drain outlet can be designed following the reference values provided in Table 7 of JB/T 13458, “Insulated Jacketed Valves.”

(6) Additional Design Considerations

To reduce the impact of impurities on valve longevity, a shaft seal is installed at the bottom of the bearing, employing materials such as flexible graphite or spring-loaded sealing rings. For specific applications, a flushing device can be added to provide enhanced protection for tightly fitted components, such as bearings, thereby extending the valve’s service life.

Figure 4 Schematic of Jacket and Bearing Space

Figure 5 Temperature Distribution Cloud Map

Table 2 Flange Dimensions Before and After Diameter Change

|

Nominal Diameter |

DN500 |

DN500 Diameter Change DN600 |

|

Flow Channel Diameter d/mm |

500 |

500 |

|

Valve Body Wall Thickness 1/mm |

16 |

16 |

|

Chamfer Height 1/mm |

5 |

5 |

|

Flange Center K |

635 |

749.3 |

|

Flange Bolts |

M30 |

M33 |

|

Number of Flange Bolts |

20 |

20 |

|

Flange Thickness |

41.3 |

46.1 |

|

Lever Arm Length 4/mm |

46.5 |

103.65 |

Figure 6 Valve Body Stress Strength Analysis

In practical applications, all components of the triple-eccentric insulated jacketed butterfly valve that come into contact with the process medium must meet the requirements for sulfur resistance and tail-gas corrosion resistance. To enhance corrosion resistance and ensure adequate hardness of the sealing surfaces, a layer of Stellite alloy is applied to the valve body’s sealing pair, thereby improving durability and extending the valve’s service life. When selecting internal components, all materials must possess corrosion resistance that meets or exceeds the user’s specified requirements. In particular, the valve stem material must offer both high corrosion resistance and sufficient mechanical strength. For this specialized butterfly valve design, XM-19, 17-4PH, or 660 stainless steel is recommended. High-strength materials are used, and the bearings are thickened and lengthened to satisfy load-bearing and operational performance requirements. Surface hardening treatments are applied to establish a controlled hardness differential relative to the valve stem, enhancing wear resistance. The sealing ring uses a proven sandwich composite design, featuring graphite as the non-metallic layer and 2205 duplex stainless steel—or other high-strength, corrosion-resistant metals—as the metallic component. The materials for the steam jacket and steam-flange interfaces are primarily selected based on steam characteristics, environmental conditions, manufacturability, and cost considerations; accordingly, carbon steel is generally preferred.

This paper uses the tail-gas-to-tail-gas reheat operation of a Claus sulfur recovery unit as a case study to summarize the structural design and operational characteristics of a triple-eccentric insulated jacketed butterfly valve. It presents the design values for valve body wall thickness, flange connection dimensions, triple-eccentric motion principles, and eccentricity parameters, with particular emphasis on the jacketed system design. The following conclusions can be drawn:

- For design parameters with established standards—such as valve body wall thickness, flange connection dimensions, and flange spacing—these standards should be strictly followed, while practical considerations must also be fully accounted for during implementation.

- Among the factors affecting the triple-eccentric parameters, their relative significance varies. To minimize operating torque, the second eccentricity should be kept as small as possible, while ensuring that the valve stem’s strength remains the primary design priority. Changes in valve diameter reduce flange stiffness, making it necessary to add reinforcing plates to improve rigidity. The jacket design must consider medium flow, circulation, bearing placement, and structural strength, while auxiliary features should be implemented to protect the bearings and prevent jamming.

- As global environmental awareness rises and the demand for energy conservation and emission reduction grows, exhaust gas recovery systems are increasingly deployed—particularly for sulfur-containing gas treatment—where process requirements are becoming progressively more advanced. Consequently, the demand for valves suitable for such operating conditions is increasing, and this study provides a valuable reference for designing valves under similar or comparable service environments.