With the rapid development of the offshore oil industry and the continuous expansion of oil reservoirs, unmanned platforms will be widely used in the Bohai Rim region. The overall size of such platforms is small, generally two to three floors, and they rely on nearby large offshore platforms to provide power or energy supply. The platform has simple processing technology and less processing equipment, and crude oil is transported to nearby processing platforms through submarine pipes after simple processing. This platform changes the existing operation mode, greatly reduces the cycle and workload of on-site patrol personnel, ensures the safety of patrol operators and reduces environmental pollution, so as to However, the scale of the unmanned platform is small and the space is tight, so the design of pipelines from layout to support, especially some small-sized pipelines and valves, is difficult.

Therefore, this paper will focus on the layout and application of small-sized pipeline electric valves for unmanned platforms, which will provide design reference for people in the same industry, and lay a good foundation for the future digital and intelligent construction of the platform.

Design requirements of electric ball valve

Unmanned design improves the automation and digitization level of the platform, adopts advanced, mature and reliable technology, simplifies the technological process, and realizes the rationality and feasibility of the unmanned operation. The unmanned design lays a good foundation for digitalization and intelligence by improving the automation level, which requires on-site remote monitoring and operation in pipeline design. An electric ball valve instead of an ordinary valve is the first step to realizing remote control. The application of the electric ball valve and the ordinary manual ball valve is shown in the following table 1:

Table 1 Comparison table of valves

To sum up, the electric valve has an absolute advantage in realizing unmanned platform through its remote operation start and stop. However, compared with ordinary valves, the electric actuator occupies a large space and is difficult to arrange centrally, especially on small-sized pipelines, where the size of the pipeline itself is small. Because the thickness and strength of the pipeline at atmospheric pressure will be affected by the weight of the valve, the service life of the pipeline will be reduced, and the leakage of the weld joint will be caused.

Arrangement of common electric valves and design of supports

According to the process flow, small-sized pipelines are set at the high and low discharge points. The most common ones are generally set at the top of the filter and the outlet of the pump, which is mainly used for pressure relief before the pump starts. If the centrifugal pump needs to be pumped before starting according to its working principle, the exhaust line can be used to monitor whether the pump is filled with pumping liquid to confirm whether the pump can be started normally. However, for unmanned platforms, electric ball valves can be used in these two positions to facilitate remote operation. However, the following problems need to be considered in the pipeline layout: firstly, the occupied space of electric valves and actuators can generally be simulated by 3D on the overall dimensions of actuators with reference to manufacturers' data, and some manufacturers can also provide dimensional models of actuators. Generally, the error is relatively small, so that the design space will be more accurate and there will be no error. However, the cable wiring position and cable wiring stuffing box space should also be considered in the design, as well as the operation of the valve handwheel, the disassembly and maintenance space of the valve at the later stage and the display screen. Secondly, the bearing capacity of the pipeline to the valve in the normal operation state is generally that the straight section of the discharge pipeline is short and the relative strength is better. According to the weight of the valve and the wall thickness of the pipeline, the stress calculation and simulation analysis of the pipeline strength in the normal operation state is carried out to confirm that the pipeline strength can bear the weight of the whole valve. Finally, it is necessary to analyze the special working conditions, such as the vibration of the pump in the actual operation process. The electric ball valve is arranged on the outlet riser of the pump, and the actuator of the valve itself has a certain weight. The pipeline is subjected to the force of gravity for a long time, which may easily cause the flange to loosen or the welding seam to open and cause pipeline leakage. Especially when the pipeline vibrates, the situation will be aggravated. Therefore, in the design process, it is necessary to consider supporting and fixing the electric ball valve on the riser to achieve the purpose of strengthening the weld root. To reduce the vibration frequency of the valve, a bracket is attached to the valve to achieve a fixed function. Conventional practice is to attach the bracket to the valve and then fix it on the deck. However, with the vibration of the pump, the pipeline will vibrate at the same frequency as the pump, and the bracket will be fixed on the deck so that there will be friction or collision between the valve and the bracket, which will easily cause the contact position between the valve and the bracket to be damaged. To avoid this situation, it is advisable to fix the bracket on the outlet pipeline of a large-sized pump that vibrates at the same frequency nearby and fix the supporting small pipe through a large pipe.

Bracket arrangement of small-sized electric valve

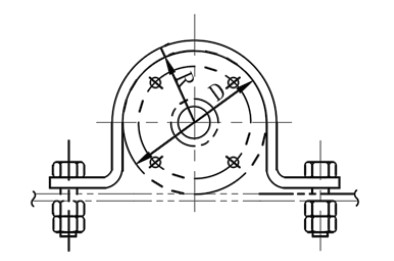

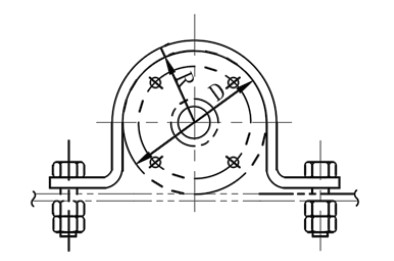

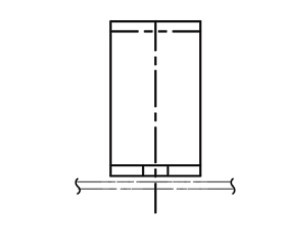

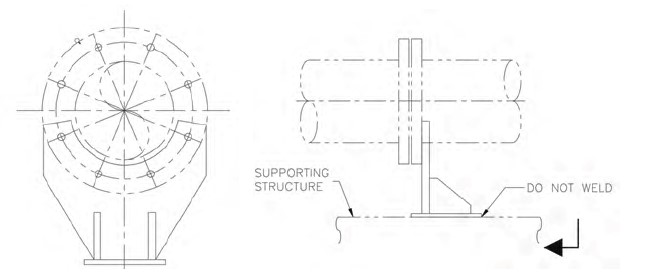

Generally, there are two kinds of supports commonly used for fixed support of small-sized valves: flange supports and flange straps, as shown in Figure 1-Figure 2:

Figure 1 Flange strap bracket

Figure 1 shows the flange strap. The whole bracket is held on the outer wall of the flange, which has achieved the function of fixing and supporting fixing the flange. However, when using this bracket, it is generally necessary to install it in advance, because some jumpers will be welded on the flange by the electrical major in the later period, which will conflict with the position of the pipe clamp. If it is added in the later period, it is necessary to negotiate with the electrical major to adjust the position of the jumpers to ensure the normal installation of the bracket.

Figure 2 Flange bracket

Figure 2 shows the flange bracket, which is suitable for FRP and low-grade flange support. It can be fixed on the bolt hole of the flange to achieve the function of fixing and supporting the flange. However, this bracket needs to increase the length of the bolt because of its certain thickness, and it is inconvenient to use if the valve is frequently disassembled.

In addition, the electric ball valve installed at the outlet of the filter should consider the performance and medium of the filter, the frequency of disassembly and cleaning of the filter, and the valve should not be installed at the top of the filter as far as possible or affect the space for opening the cover and core pulling of the filter because the number and time of people boarding the platform for maintenance are generally limited in unmanned platforms. If the valve affects the core pulling of the filter, the valve needs to be temporarily removed on site, but the electric valve is heavy and difficult to disassemble, which consumes too much manpower and time. Therefore, in the pipeline layout, try to avoid the space for filter core-pulling operation and maintenance, and take the pipeline to the position with sufficient space for easy operation and maintenance, and then install the valve to facilitate the subsequent operation and maintenance.

Conclusion

By analyzing the layout and application of common valves and electric valves, this paper gives a common layout of small-sized electric ball valves, and a series of Chinese considerations in the design process, which provides a reference for people in the same industry. Compared with conventional fixed platforms, the layout of electric ball valves on unmanned platforms is more complicated, and with the development of the offshore oil industry, the application of unmanned platforms will be more extensive.

Therefore, this paper will focus on the layout and application of small-sized pipeline electric valves for unmanned platforms, which will provide design reference for people in the same industry, and lay a good foundation for the future digital and intelligent construction of the platform.

Design requirements of electric ball valve

Unmanned design improves the automation and digitization level of the platform, adopts advanced, mature and reliable technology, simplifies the technological process, and realizes the rationality and feasibility of the unmanned operation. The unmanned design lays a good foundation for digitalization and intelligence by improving the automation level, which requires on-site remote monitoring and operation in pipeline design. An electric ball valve instead of an ordinary valve is the first step to realizing remote control. The application of the electric ball valve and the ordinary manual ball valve is shown in the following table 1:

Table 1 Comparison table of valves

| Content | Common Valves | Electric Ball Valves |

| Valve size and occupied space | The valve is small in volume | Valves and actuating mechanism |

| Valve weight | Valve weight | Valve+actuating mechanism weight |

| Valve installing position | level or verticle | The level is good, the vertical needs to be calculated by the manufacturer, and a supportable position on the valve is provided. |

| Valve operation and maintenance space | Normal manual operation space | Valve handwheel operation+actuator+wiring space can realize remote start-stop operation. |

| Pipeline wall thickness strength requirements | Normal pipeline wall thickness strength | Depending on the weight and operating space of the valve and actuators |

| Cost | Low cost | High cost |

To sum up, the electric valve has an absolute advantage in realizing unmanned platform through its remote operation start and stop. However, compared with ordinary valves, the electric actuator occupies a large space and is difficult to arrange centrally, especially on small-sized pipelines, where the size of the pipeline itself is small. Because the thickness and strength of the pipeline at atmospheric pressure will be affected by the weight of the valve, the service life of the pipeline will be reduced, and the leakage of the weld joint will be caused.

Arrangement of common electric valves and design of supports

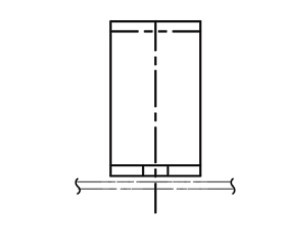

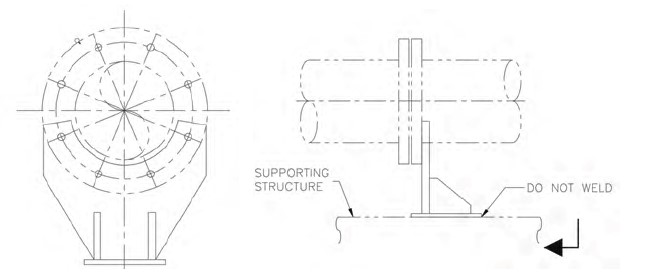

According to the process flow, small-sized pipelines are set at the high and low discharge points. The most common ones are generally set at the top of the filter and the outlet of the pump, which is mainly used for pressure relief before the pump starts. If the centrifugal pump needs to be pumped before starting according to its working principle, the exhaust line can be used to monitor whether the pump is filled with pumping liquid to confirm whether the pump can be started normally. However, for unmanned platforms, electric ball valves can be used in these two positions to facilitate remote operation. However, the following problems need to be considered in the pipeline layout: firstly, the occupied space of electric valves and actuators can generally be simulated by 3D on the overall dimensions of actuators with reference to manufacturers' data, and some manufacturers can also provide dimensional models of actuators. Generally, the error is relatively small, so that the design space will be more accurate and there will be no error. However, the cable wiring position and cable wiring stuffing box space should also be considered in the design, as well as the operation of the valve handwheel, the disassembly and maintenance space of the valve at the later stage and the display screen. Secondly, the bearing capacity of the pipeline to the valve in the normal operation state is generally that the straight section of the discharge pipeline is short and the relative strength is better. According to the weight of the valve and the wall thickness of the pipeline, the stress calculation and simulation analysis of the pipeline strength in the normal operation state is carried out to confirm that the pipeline strength can bear the weight of the whole valve. Finally, it is necessary to analyze the special working conditions, such as the vibration of the pump in the actual operation process. The electric ball valve is arranged on the outlet riser of the pump, and the actuator of the valve itself has a certain weight. The pipeline is subjected to the force of gravity for a long time, which may easily cause the flange to loosen or the welding seam to open and cause pipeline leakage. Especially when the pipeline vibrates, the situation will be aggravated. Therefore, in the design process, it is necessary to consider supporting and fixing the electric ball valve on the riser to achieve the purpose of strengthening the weld root. To reduce the vibration frequency of the valve, a bracket is attached to the valve to achieve a fixed function. Conventional practice is to attach the bracket to the valve and then fix it on the deck. However, with the vibration of the pump, the pipeline will vibrate at the same frequency as the pump, and the bracket will be fixed on the deck so that there will be friction or collision between the valve and the bracket, which will easily cause the contact position between the valve and the bracket to be damaged. To avoid this situation, it is advisable to fix the bracket on the outlet pipeline of a large-sized pump that vibrates at the same frequency nearby and fix the supporting small pipe through a large pipe.

Bracket arrangement of small-sized electric valve

Generally, there are two kinds of supports commonly used for fixed support of small-sized valves: flange supports and flange straps, as shown in Figure 1-Figure 2:

Figure 1 Flange strap bracket

Figure 1 shows the flange strap. The whole bracket is held on the outer wall of the flange, which has achieved the function of fixing and supporting fixing the flange. However, when using this bracket, it is generally necessary to install it in advance, because some jumpers will be welded on the flange by the electrical major in the later period, which will conflict with the position of the pipe clamp. If it is added in the later period, it is necessary to negotiate with the electrical major to adjust the position of the jumpers to ensure the normal installation of the bracket.

Figure 2 Flange bracket

Figure 2 shows the flange bracket, which is suitable for FRP and low-grade flange support. It can be fixed on the bolt hole of the flange to achieve the function of fixing and supporting the flange. However, this bracket needs to increase the length of the bolt because of its certain thickness, and it is inconvenient to use if the valve is frequently disassembled.

In addition, the electric ball valve installed at the outlet of the filter should consider the performance and medium of the filter, the frequency of disassembly and cleaning of the filter, and the valve should not be installed at the top of the filter as far as possible or affect the space for opening the cover and core pulling of the filter because the number and time of people boarding the platform for maintenance are generally limited in unmanned platforms. If the valve affects the core pulling of the filter, the valve needs to be temporarily removed on site, but the electric valve is heavy and difficult to disassemble, which consumes too much manpower and time. Therefore, in the pipeline layout, try to avoid the space for filter core-pulling operation and maintenance, and take the pipeline to the position with sufficient space for easy operation and maintenance, and then install the valve to facilitate the subsequent operation and maintenance.

Conclusion

By analyzing the layout and application of common valves and electric valves, this paper gives a common layout of small-sized electric ball valves, and a series of Chinese considerations in the design process, which provides a reference for people in the same industry. Compared with conventional fixed platforms, the layout of electric ball valves on unmanned platforms is more complicated, and with the development of the offshore oil industry, the application of unmanned platforms will be more extensive.