Overview of Domestic Valve Market

As a key component of pipeline fluid control, plastic valves are widely used in the natural gas pipeline, heat pump heating and refrigeration pipeline system, agricultural irrigation system, domestic hot and cold water system, chemical and pharmaceutical pipeline system, water treatment system and electroplating pipeline system. At present, the total demand of domestic valve market is around 300 billion yuan (the data comes from the data in the article "Analysis of the present situation and development trend of China's valve industry in 2016", and the main business income of domestic valves in 2015 was 256.6 billion yuan); According to the data released by China Customs, in 2017, China's valve imports amounted to US$ 6.109 billion (41.247 billion yuan at the then average exchange rate), and in 2018, the valve imports amounted to US$ 7.328 billion (48.492 billion yuan at the then average exchange rate), which increased by 19.95% in terms of US dollars compared with 2017. The rapid growth of imported valves indicates that the domestic demand for high-quality valves is increasing. At present, the domestic metal valves still account for the majority of the market share. Except for the high-temperature and high-pressure pipeline system, the metal valves used in most pipelines can be replaced by plastic valves. In some industrial fields, the corrosion resistance and service life of plastic valves are superior to those of metal valves, but at present, plastic valves account for a relatively small proportion in the whole valve market. At present, there are not many domestic manufacturers specializing in the production of plastic valves, only some manufacturers of plastic valves used in chemical pipelines and companies supporting plastic valves for plastic pipeline manufacturers. Most of the production scale is not large, the product quality is uneven, and most of the plastic valve products are not designed formally according to the standards, but simply copied the plastic valve products sold in the market, resulting in some plastic valve enterprises that invested millions to tens of millions of dollars, which closed down due to inadequate product design and unqualified quality.

Quality Status and Market Demand of Plastic Valves in China

Polyethylene (PE) natural gas valves are strictly controlled by natural gas companies and other departments due to the particularity of application fields, and there are relatively few domestic production enterprises. The national standard "Buried polyethylene (PE) pipeline system for gas-Part 3: valves" GB/T15558.3-2008 was published earlier, so the product quality in the market is relatively stable. However, plastic ball valves and plastic gate valves have not been subject to national standards before, so the product quality of this kind of plastic valves has not been effectively controlled, and the product quality on the market is mixed. In some systems, the fatigue strength of power-driven control valves is more than 100,000 times (the fatigue strength of plastic valves refers to the number of times that the valves can be opened and closed without leakage under the conditions of specified water temperature, nominal pressure and specified flow rate in the valves). At present, the fatigue strength of some plastic valves in China is about 15,000 times, and there is still much room for improvement of product quality. According to the product standard requirements of plastic valves, the service life is not less than 25 years, and the opening and closing times of 15,000 times are only 1.6 times per day, which can only meet the pipeline systems that are not frequently opened and closed every day but can not meet the pipeline systems similar to those that need frequent adjustment, such as HVAC. It is understood that there is a radiant panel heating, refrigeration and fresh air dehumidification system, and the control valve is opened and closed about 20 times a day, which requires the valve to run about 3,650 times in winter and summer every year, and it needs to run more than 90,000 times in a 25-year life cycle. Valves with less fatigue intensity are far from meeting the requirements of this system.

The minimum flow diameter/inflow cross-sectional area of many domestic plastic valves (including metal valves) products is smaller than the inner diameter/flow cross-sectional area of the pipeline, which will increase the fluid transmission resistance of the pipeline; There are also some plastic valves whose sealing materials are not enough, which makes the valves prone to internal leakage and external leakage. There are also some plastic valve products whose shell strength is less than that of the connected plastic pipes, which can not meet the requirements of normal use. See the right picture in Figure 1. The 1000-hour pressure test broke down after only ten hours. This kind of valve was not designed according to the overall strength, resulting in weak local strength. Of course, there are also some domestic manufacturers whose fatigue strength of plastic valve products can reach more than 100,000 times. There are also varieties of valves such as PVC-C, PVDF and PPO/PPE. The bearing strength of these valves is higher than that of existing plastic pipes made of PP-R, PE-X, PE-RT and other materials, and they are worthy of attention.

Fig.1 The strength of the plastic valve product shell is less than that of the plastic pipe it is connected to

Main Requirements and Selection of Plastic Valves

1. Valve size

The size term of the plastic valve comes from GB/T19278-2018 General Terms and Definitions of Thermoplastic Pipes, Fittings and Valves.

Clearway valve: a valve with a barrier-free flow channel, which theoretically allows a ball with a diameter equal to the inner diameter of the inlet of the valve to pass through. Fully open valve, also known as full bore valve in the pipeline industry. Full bore valve: a plastic valve whose minimum flow cross-sectional area is not less than 80% of the inflow cross-sectional area of the valve (except the socket). Reduced bore valve: a valve whose minimum flow cross-sectional area is less than 80% but not less than 36% of the inflow cross-sectional area of the valve (except the socket).

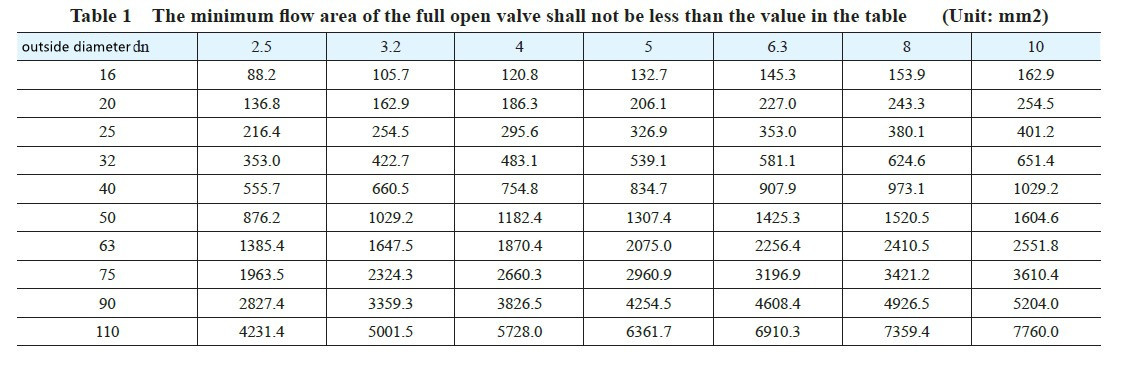

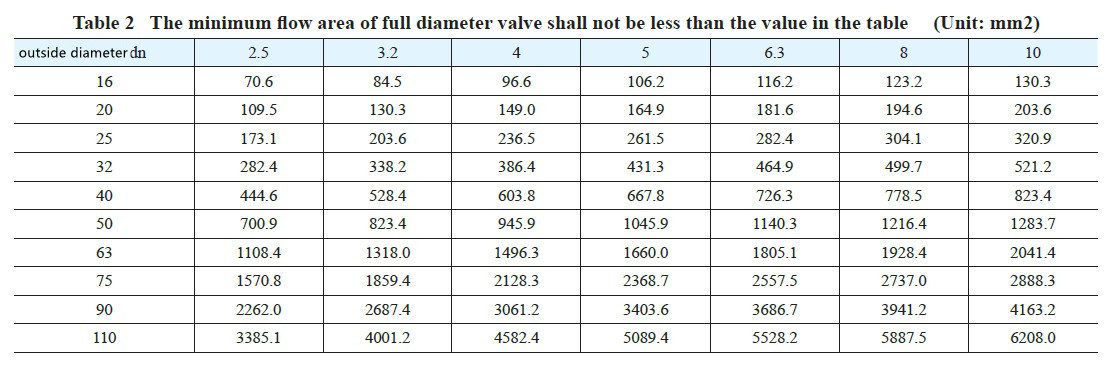

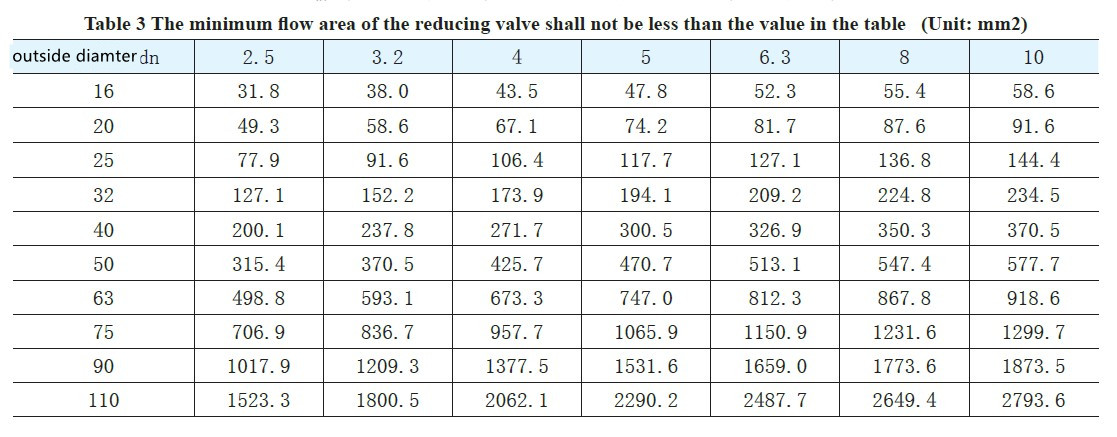

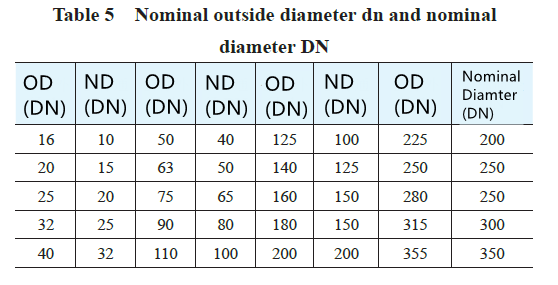

See Table 1 for the flow area of all kinds of commonly used plastic full-open valves.

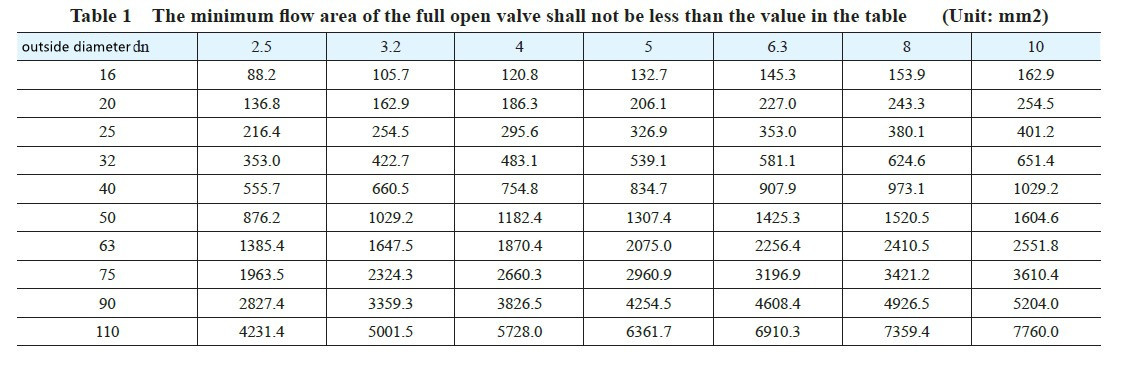

See Table 2 for the flow area of various commonly used plastic full-diameter valves.

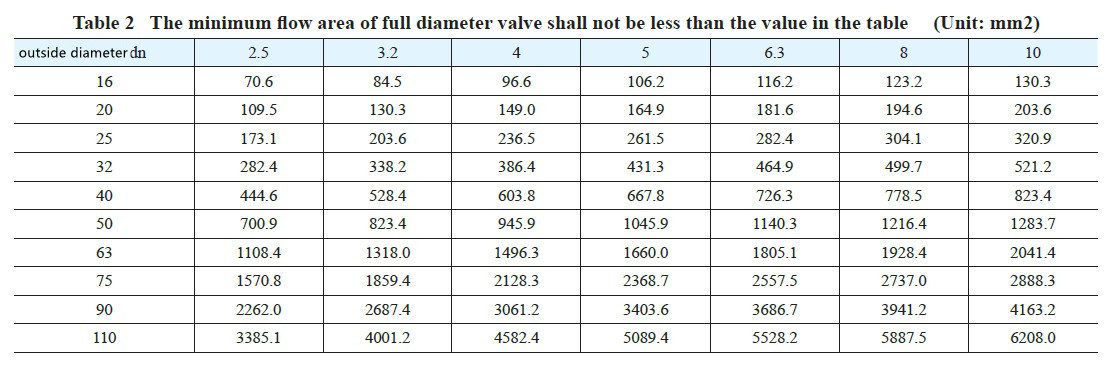

See Table 3 for the flow area of various commonly used plastic reducing valves.

These three tables are only used as a reference for the selection of some specifications of plastic valves when connecting with plastic pipes. Other specifications of plastic valves can be calculated according to the inner diameters of different pipe series S given in the General Wall Thickness Table of Thermoplastic Pipe GB/T10798-2001. One of the same principles for the selection of plastic valves and metal valves is that the flow area/minimum diameter should be as close as possible to the inner diameter area/inner diameter of pipes, so as to reduce the local resistance of valves with the same structure in the pipeline.

Table 1 The minimum flow area of the fully open valve can not be less than the numerical unit in the table: square millimeter.

Table 2 The minimum flow area of the full-diameter valve cannot be less than the numerical unit in the table: square millimeter.

Table 3 The minimum flow area of the reducing valve can not be less than the numerical unit in the table: square millimeter.

2. Wall thickness requirements of plastic valves

The wall thickness of all pressure-bearing parts of plastic valves should meet the strength calculation of Pressure Vessels Part 3: Design GB/T 150.3—2011, and its wall thickness should be greater than that of pipes of the same material, pipe series and specifications.

3. Selection of plastic valves

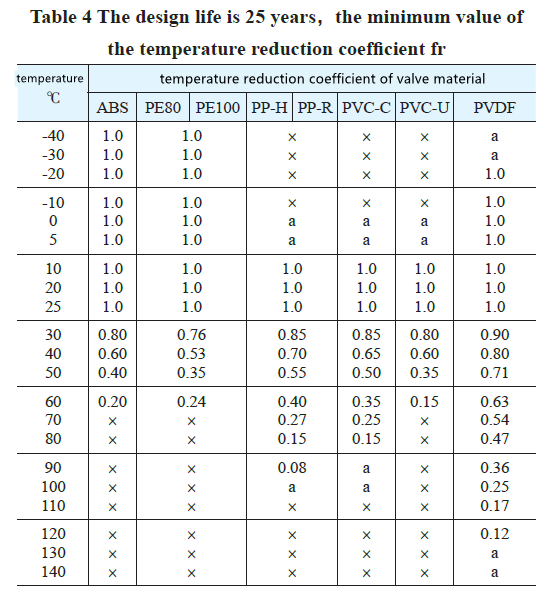

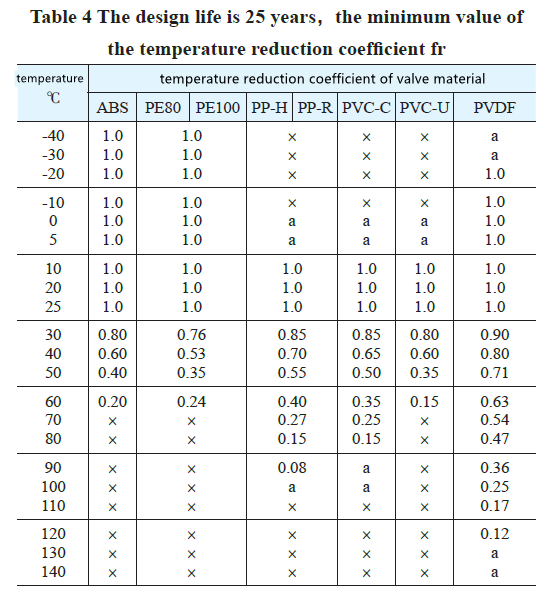

Select products according to the service pressure, temperature and opening and closing times of the valve under nominal pressure in the service life cycle of the system. For example, a pipeline system needs to open and close the valve three times a day, that is, 1095 times a year, and the service life of 25 years needs to meet 27,375 operations, so it is necessary to select products with the fatigue strength of the valve meeting 30,000 times. Of course, if the system pressure of the selected valve is lower than the nominal pressure of the valve, the opening and closing times in the life cycle may also increase. Polyvinylidene fluoride (PVDF), acrylonitrile butadiene styrene (ABS), hard polyvinyl chloride (PVC-U), chlorinated polyvinyl chloride (PVC-C), polybutene (PB), polyethylene (PE), heat-resistant polyethylene (PE-RT) and cross-linked polyethylene (PE-X) According to the design temperature and pressure of the piping system, refer to Table 4 to select plastic valves of different materials. It can be seen from Table 4 that the PVDF valve has the best temperature resistance and pressure resistance.

It is the reduction coefficient fr with a service life of 25 years, which is inconsistent with the reduction coefficient of pipes and fittings. Table × should not be used. The reduction factor in table A is given by the manufacturer.

Table 4 Minimum value of temperature reduction coefficient fr when the design life is 25 years

4. Selection of valve size flow cross-sectional area/minimum size

In order to reduce the local resistance of the pipeline, fully open valves should be selected as much as possible. The selection of the plastic valve size should be based on the inner diameter of the pipeline where the plastic valve is assembled, and can not be selected only by the plastic valve size identification. The full-diameter valve of the S8 series with the same nominal outer diameter may be the full-open valve of the S4 series pipeline, and the full-open valve of the S2.5 series may be the reducing valve of the S4 series pipeline.

5. Pay attention to hygiene performance when choosing plastic valves.

For the pipeline system with hygienic performance requirements, the materials in contact with the medium on the plastic valve should meet the hygienic performance requirements. In addition, all plastic valves should be assembled without lubricant to ensure the sanitary performance of the valves.

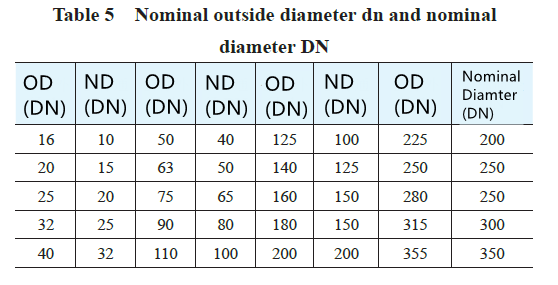

6. Comparison of path symbols of plastic valves and metal valves

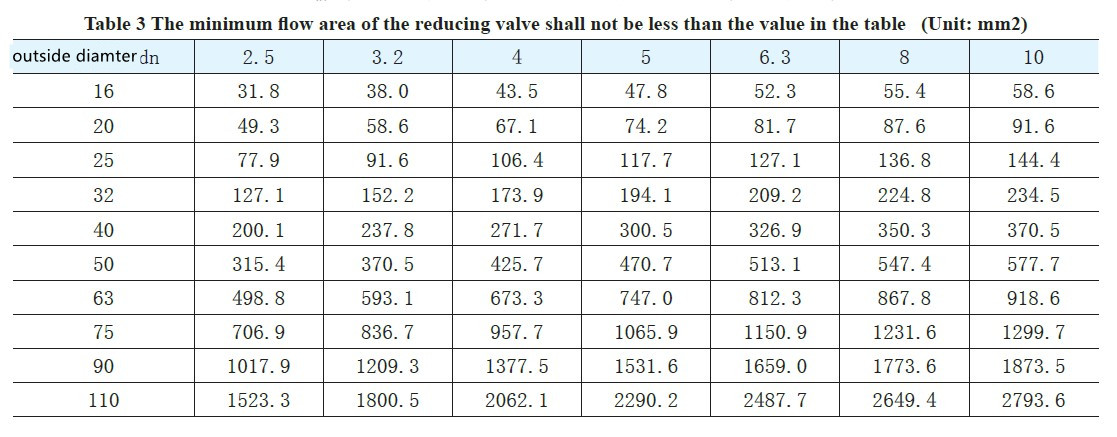

The diameter representation method of metal valves is DN, and that of plastic valves is consistent with the nominal outer diameter DN of plastic pipes. See Table 5 for the comparison between nominal diameter DN and nominal outer diameter DN.

Table 5 The comparison relationship between nominal outer diameter DN and nominal diameter DN is in millimeters.

Standard of Plastic Valves

National standards for plastic valve products have been released, including buried polyethylene (PE) pipeline system for gas part 3 valves GB 15558.3-2008, rigid polyvinyl chloride (PVC-U) valves for water supply GB/T10002.3-2011, thermoplastic butterfly valves GB/T27725-2011, and PVC valves for water supply GB/T27725-2011. This year, under the leadership of TC48/SC3, the Technical Committee for Pipe Fittings and Valves of National Plastics Standardization Technical Committee, two plastic valve standards, Thermoplastic Ball Valve GB/T37842-2019 and Thermoplastic Gate Valve GB/T38008-2019, were also completed. It is worth noting that many large-scale butterfly valves abroad are made of thermosetting plastics, and there is no corresponding product standard in China.

Types of Plastic Valves

Types of plastic valves can be divided into ball valves, gate valves, globe valves, butterfly valves, diaphragm valves and check valves according to their structures, and angle valves, needle valves, throttle valves, plug valves, safety valves, pressure reducing valves, steam traps and regulating valves according to their uses. Fig. 2 to fig. 7 are some foreign plastic valve products with the same structure but different materials. It should be noted that the wall thickness of plastic valves with the same specifications should also be different.

Fig.2 PVC、CPVC、PP、PVDF FYFRS

Fig.3 PVC、PP、PVDF wafer check valve

Fig.4 PVC、CPVC、PP、PVDF membrane valve

Fig.5 PVC、PP stop valve

Fig.6 PVC Plug valve

Fig.7 PVDF butterfly valve

Market Competitive Advantage of Plastic Valves

(1) good sanitary performance and no precipitation of heavy metals;

(2) The corrosion resistance is better than that of cast iron valves, steel valves, copper valves and stainless steel valves;

(3) The plastic valve is light in weight, which is convenient to install and reduce the installation load of the pipeline;

(4) The service life is not less than 25 years, and some valves can be maintenance-free;

(5) In the system of seasonal use, it will not affect the opening and closing operation of the valve when it is used again because some substances in the transmission medium are adsorbed on the valve sealing parts;

(6) Compared with metal valves, the cost performance of plastic valves is high, which adds a comparative choice for users.

The two valves in fig. 8 are all copper products installed in tap water pipes. The left picture shows a copper ball valve and the right picture shows a copper angle valve. It can be seen that the corrosion resistance and adsorption resistance of metal valves are weaker than those of plastic valves, especially those of cast iron valves. Therefore, the Catalogue of Prohibited Use of Building Materials in Beijing (2018 Edition) points out that the reason why the internally threaded cast iron valves for plumbing are prohibited is that the cast iron valves are easy to rust.

Fig.8 Condition of the copper valve after long service

Metal valves and plastic valves need to be decided according to the requirements of the pipeline system and the amount of investment in the pipeline system. The high-temperature resistance of plastic valves is weaker than that of metal valves, and each has its own advantages and disadvantages. There are not many manufacturers specializing in producing plastic valves in China, and the market prospect of plastic valves is very broad. I hope that manufacturers of plastic valves will strictly control the product quality and gradually improve the technical indexes of products. The indexes specified in ISO plastic valve standard only give the minimum requirements of products, and some indexes in the national plastic valve standard are higher than those specified in ISO plastic valve standard. However, if we want to meet some pipeline systems with frequent control requirements, Some indicators need to be further improved. From the perspective of improving the quality and comprehensive performance of plastic valves, PVDF valves deserve attention. In the future, professional plastic valve manufacturers still have a long way to go, and it is necessary to continuously improve the service performance of plastic valves to meet the development needs of various pipeline systems.

As a key component of pipeline fluid control, plastic valves are widely used in the natural gas pipeline, heat pump heating and refrigeration pipeline system, agricultural irrigation system, domestic hot and cold water system, chemical and pharmaceutical pipeline system, water treatment system and electroplating pipeline system. At present, the total demand of domestic valve market is around 300 billion yuan (the data comes from the data in the article "Analysis of the present situation and development trend of China's valve industry in 2016", and the main business income of domestic valves in 2015 was 256.6 billion yuan); According to the data released by China Customs, in 2017, China's valve imports amounted to US$ 6.109 billion (41.247 billion yuan at the then average exchange rate), and in 2018, the valve imports amounted to US$ 7.328 billion (48.492 billion yuan at the then average exchange rate), which increased by 19.95% in terms of US dollars compared with 2017. The rapid growth of imported valves indicates that the domestic demand for high-quality valves is increasing. At present, the domestic metal valves still account for the majority of the market share. Except for the high-temperature and high-pressure pipeline system, the metal valves used in most pipelines can be replaced by plastic valves. In some industrial fields, the corrosion resistance and service life of plastic valves are superior to those of metal valves, but at present, plastic valves account for a relatively small proportion in the whole valve market. At present, there are not many domestic manufacturers specializing in the production of plastic valves, only some manufacturers of plastic valves used in chemical pipelines and companies supporting plastic valves for plastic pipeline manufacturers. Most of the production scale is not large, the product quality is uneven, and most of the plastic valve products are not designed formally according to the standards, but simply copied the plastic valve products sold in the market, resulting in some plastic valve enterprises that invested millions to tens of millions of dollars, which closed down due to inadequate product design and unqualified quality.

Quality Status and Market Demand of Plastic Valves in China

Polyethylene (PE) natural gas valves are strictly controlled by natural gas companies and other departments due to the particularity of application fields, and there are relatively few domestic production enterprises. The national standard "Buried polyethylene (PE) pipeline system for gas-Part 3: valves" GB/T15558.3-2008 was published earlier, so the product quality in the market is relatively stable. However, plastic ball valves and plastic gate valves have not been subject to national standards before, so the product quality of this kind of plastic valves has not been effectively controlled, and the product quality on the market is mixed. In some systems, the fatigue strength of power-driven control valves is more than 100,000 times (the fatigue strength of plastic valves refers to the number of times that the valves can be opened and closed without leakage under the conditions of specified water temperature, nominal pressure and specified flow rate in the valves). At present, the fatigue strength of some plastic valves in China is about 15,000 times, and there is still much room for improvement of product quality. According to the product standard requirements of plastic valves, the service life is not less than 25 years, and the opening and closing times of 15,000 times are only 1.6 times per day, which can only meet the pipeline systems that are not frequently opened and closed every day but can not meet the pipeline systems similar to those that need frequent adjustment, such as HVAC. It is understood that there is a radiant panel heating, refrigeration and fresh air dehumidification system, and the control valve is opened and closed about 20 times a day, which requires the valve to run about 3,650 times in winter and summer every year, and it needs to run more than 90,000 times in a 25-year life cycle. Valves with less fatigue intensity are far from meeting the requirements of this system.

The minimum flow diameter/inflow cross-sectional area of many domestic plastic valves (including metal valves) products is smaller than the inner diameter/flow cross-sectional area of the pipeline, which will increase the fluid transmission resistance of the pipeline; There are also some plastic valves whose sealing materials are not enough, which makes the valves prone to internal leakage and external leakage. There are also some plastic valve products whose shell strength is less than that of the connected plastic pipes, which can not meet the requirements of normal use. See the right picture in Figure 1. The 1000-hour pressure test broke down after only ten hours. This kind of valve was not designed according to the overall strength, resulting in weak local strength. Of course, there are also some domestic manufacturers whose fatigue strength of plastic valve products can reach more than 100,000 times. There are also varieties of valves such as PVC-C, PVDF and PPO/PPE. The bearing strength of these valves is higher than that of existing plastic pipes made of PP-R, PE-X, PE-RT and other materials, and they are worthy of attention.

Fig.1 The strength of the plastic valve product shell is less than that of the plastic pipe it is connected to

Main Requirements and Selection of Plastic Valves

1. Valve size

The size term of the plastic valve comes from GB/T19278-2018 General Terms and Definitions of Thermoplastic Pipes, Fittings and Valves.

Clearway valve: a valve with a barrier-free flow channel, which theoretically allows a ball with a diameter equal to the inner diameter of the inlet of the valve to pass through. Fully open valve, also known as full bore valve in the pipeline industry. Full bore valve: a plastic valve whose minimum flow cross-sectional area is not less than 80% of the inflow cross-sectional area of the valve (except the socket). Reduced bore valve: a valve whose minimum flow cross-sectional area is less than 80% but not less than 36% of the inflow cross-sectional area of the valve (except the socket).

See Table 1 for the flow area of all kinds of commonly used plastic full-open valves.

See Table 2 for the flow area of various commonly used plastic full-diameter valves.

See Table 3 for the flow area of various commonly used plastic reducing valves.

These three tables are only used as a reference for the selection of some specifications of plastic valves when connecting with plastic pipes. Other specifications of plastic valves can be calculated according to the inner diameters of different pipe series S given in the General Wall Thickness Table of Thermoplastic Pipe GB/T10798-2001. One of the same principles for the selection of plastic valves and metal valves is that the flow area/minimum diameter should be as close as possible to the inner diameter area/inner diameter of pipes, so as to reduce the local resistance of valves with the same structure in the pipeline.

Table 1 The minimum flow area of the fully open valve can not be less than the numerical unit in the table: square millimeter.

Table 2 The minimum flow area of the full-diameter valve cannot be less than the numerical unit in the table: square millimeter.

Table 3 The minimum flow area of the reducing valve can not be less than the numerical unit in the table: square millimeter.

2. Wall thickness requirements of plastic valves

The wall thickness of all pressure-bearing parts of plastic valves should meet the strength calculation of Pressure Vessels Part 3: Design GB/T 150.3—2011, and its wall thickness should be greater than that of pipes of the same material, pipe series and specifications.

3. Selection of plastic valves

Select products according to the service pressure, temperature and opening and closing times of the valve under nominal pressure in the service life cycle of the system. For example, a pipeline system needs to open and close the valve three times a day, that is, 1095 times a year, and the service life of 25 years needs to meet 27,375 operations, so it is necessary to select products with the fatigue strength of the valve meeting 30,000 times. Of course, if the system pressure of the selected valve is lower than the nominal pressure of the valve, the opening and closing times in the life cycle may also increase. Polyvinylidene fluoride (PVDF), acrylonitrile butadiene styrene (ABS), hard polyvinyl chloride (PVC-U), chlorinated polyvinyl chloride (PVC-C), polybutene (PB), polyethylene (PE), heat-resistant polyethylene (PE-RT) and cross-linked polyethylene (PE-X) According to the design temperature and pressure of the piping system, refer to Table 4 to select plastic valves of different materials. It can be seen from Table 4 that the PVDF valve has the best temperature resistance and pressure resistance.

It is the reduction coefficient fr with a service life of 25 years, which is inconsistent with the reduction coefficient of pipes and fittings. Table × should not be used. The reduction factor in table A is given by the manufacturer.

Table 4 Minimum value of temperature reduction coefficient fr when the design life is 25 years

4. Selection of valve size flow cross-sectional area/minimum size

In order to reduce the local resistance of the pipeline, fully open valves should be selected as much as possible. The selection of the plastic valve size should be based on the inner diameter of the pipeline where the plastic valve is assembled, and can not be selected only by the plastic valve size identification. The full-diameter valve of the S8 series with the same nominal outer diameter may be the full-open valve of the S4 series pipeline, and the full-open valve of the S2.5 series may be the reducing valve of the S4 series pipeline.

5. Pay attention to hygiene performance when choosing plastic valves.

For the pipeline system with hygienic performance requirements, the materials in contact with the medium on the plastic valve should meet the hygienic performance requirements. In addition, all plastic valves should be assembled without lubricant to ensure the sanitary performance of the valves.

6. Comparison of path symbols of plastic valves and metal valves

The diameter representation method of metal valves is DN, and that of plastic valves is consistent with the nominal outer diameter DN of plastic pipes. See Table 5 for the comparison between nominal diameter DN and nominal outer diameter DN.

Table 5 The comparison relationship between nominal outer diameter DN and nominal diameter DN is in millimeters.

Standard of Plastic Valves

National standards for plastic valve products have been released, including buried polyethylene (PE) pipeline system for gas part 3 valves GB 15558.3-2008, rigid polyvinyl chloride (PVC-U) valves for water supply GB/T10002.3-2011, thermoplastic butterfly valves GB/T27725-2011, and PVC valves for water supply GB/T27725-2011. This year, under the leadership of TC48/SC3, the Technical Committee for Pipe Fittings and Valves of National Plastics Standardization Technical Committee, two plastic valve standards, Thermoplastic Ball Valve GB/T37842-2019 and Thermoplastic Gate Valve GB/T38008-2019, were also completed. It is worth noting that many large-scale butterfly valves abroad are made of thermosetting plastics, and there is no corresponding product standard in China.

Types of Plastic Valves

Types of plastic valves can be divided into ball valves, gate valves, globe valves, butterfly valves, diaphragm valves and check valves according to their structures, and angle valves, needle valves, throttle valves, plug valves, safety valves, pressure reducing valves, steam traps and regulating valves according to their uses. Fig. 2 to fig. 7 are some foreign plastic valve products with the same structure but different materials. It should be noted that the wall thickness of plastic valves with the same specifications should also be different.

Fig.2 PVC、CPVC、PP、PVDF FYFRS

Fig.3 PVC、PP、PVDF wafer check valve

Fig.4 PVC、CPVC、PP、PVDF membrane valve

Fig.5 PVC、PP stop valve

Fig.6 PVC Plug valve

Fig.7 PVDF butterfly valve

Market Competitive Advantage of Plastic Valves

(1) good sanitary performance and no precipitation of heavy metals;

(2) The corrosion resistance is better than that of cast iron valves, steel valves, copper valves and stainless steel valves;

(3) The plastic valve is light in weight, which is convenient to install and reduce the installation load of the pipeline;

(4) The service life is not less than 25 years, and some valves can be maintenance-free;

(5) In the system of seasonal use, it will not affect the opening and closing operation of the valve when it is used again because some substances in the transmission medium are adsorbed on the valve sealing parts;

(6) Compared with metal valves, the cost performance of plastic valves is high, which adds a comparative choice for users.

The two valves in fig. 8 are all copper products installed in tap water pipes. The left picture shows a copper ball valve and the right picture shows a copper angle valve. It can be seen that the corrosion resistance and adsorption resistance of metal valves are weaker than those of plastic valves, especially those of cast iron valves. Therefore, the Catalogue of Prohibited Use of Building Materials in Beijing (2018 Edition) points out that the reason why the internally threaded cast iron valves for plumbing are prohibited is that the cast iron valves are easy to rust.

Fig.8 Condition of the copper valve after long service

Metal valves and plastic valves need to be decided according to the requirements of the pipeline system and the amount of investment in the pipeline system. The high-temperature resistance of plastic valves is weaker than that of metal valves, and each has its own advantages and disadvantages. There are not many manufacturers specializing in producing plastic valves in China, and the market prospect of plastic valves is very broad. I hope that manufacturers of plastic valves will strictly control the product quality and gradually improve the technical indexes of products. The indexes specified in ISO plastic valve standard only give the minimum requirements of products, and some indexes in the national plastic valve standard are higher than those specified in ISO plastic valve standard. However, if we want to meet some pipeline systems with frequent control requirements, Some indicators need to be further improved. From the perspective of improving the quality and comprehensive performance of plastic valves, PVDF valves deserve attention. In the future, professional plastic valve manufacturers still have a long way to go, and it is necessary to continuously improve the service performance of plastic valves to meet the development needs of various pipeline systems.