Abstract

To address the insufficient reliability of marine valves in harsh marine environments, this study proposes a full-process quality control method. By optimizing key stages—including material selection, structural design, manufacturing processes, and assembly testing—a comprehensive quality assurance system is established. Through a combination of theoretical analysis, numerical simulation, and experimental validation, the results show that this method improves valve sealing performance and durability, providing a systematic quality control framework for marine valve manufacturing. This approach provides significant practical value for enhancing the reliability of marine equipment and promoting technological advancement within the industry.

Marine valves are essential fluid control devices in ship piping systems, responsible for regulating pressure, directing flow, and ensuring overall system safety. Unlike land-based valves, marine valves are subjected to prolonged exposure to salt spray, high humidity, and turbulent conditions. Consequently, they require materials with excellent corrosion resistance, such as nickel–aluminum bronze and specialized stainless steels. Valve stems are often treated with hard chrome plating or nitriding to improve wear resistance. Owing to the limited space in ship engine rooms, marine valves often feature compact designs, achieving miniaturization and reduced weight through optimized flow paths and transmission mechanisms. Marine valves are available in various types, including gate valves, globe valves, ball valves, and other specialized designs. Examples include hydraulically actuated butterfly valves for engine-room fire protection, remote-controlled valves with emergency manual overrides, and cavitation-resistant valves. Different media systems impose specific requirements: fuel systems require static discharge prevention, while oxygen systems necessitate degreasing and copper-free treatments. Civilian marine valves must receive type approval from classification societies, whereas naval valves must additionally comply with military standards, including explosion resistance and electromagnetic compatibility. With stricter environmental regulations, new low-leakage and ultra-low-temperature eco-friendly valves are emerging, spurring advancements in valve manufacturing technologies. Researchers in China and abroad have conducted extensive studies on marine valves, focusing on areas such as packing seal optimization, control strategy enhancement, intelligent identification methods, and flow path design. Although significant progress has been made in certain areas, challenges persist regarding material adaptability, reliability under extreme operating conditions, and the integration of intelligent features in complex marine environments. Against this backdrop, this paper systematically examines full-process quality control methods for marine valves, highlighting key control points in material selection, structural design, manufacturing processes, and assembly testing. These measures improve sealing performance and durability, extend service life, and enhance adaptability to harsh marine environments.

The primary materials used in marine valve manufacturing include cast iron, carbon steel, stainless steel, copper alloys, titanium alloys, and aluminum alloys. Each material is suitable for specific operating environments and media conditions, as summarized in Table 1.

Table 1. Material Selection for Marine Valves

|

Category |

Grade |

Applicable Media |

Applicable Temperature |

Key Features |

|

Cast Iron |

H1200, H1250, Q7400-15 |

Fresh water, air, low-pressure steam |

-20°C to 250°C |

Low cost, good casting properties, poor corrosion resistance; unsuitable for seawater |

|

Carbon Steel |

WCB, WCC, LCB |

Fuel oil, lubricating oil, high-pressure steam |

-29°C to 425°C |

High strength, good pressure resistance; requires surface corrosion protection |

|

Stainless Steel |

304 (06Cr19Ni10), 316 (06Cr17Ni12Mo2) |

Seawater, chemicals, high-temperature steam |

-196°C to 600°C |

Excellent corrosion resistance; suitable for salt-spray environments |

|

Copper Alloys |

ZCuSnSPb5Zn5 (Tin Bronze), ZCuAl9Fe4Ni4Mn2 (Nickel Aluminum Bronze) |

Seawater, fresh water, fuel oil |

-40°C to 300°C |

Excellent seawater corrosion resistance, antibacterial properties; higher cost |

|

Titanium Alloys |

TA2, TAS, TC4 |

Seawater, strong acids, strong alkalis |

-196°C to 350°C |

Outstanding corrosion resistance, lightweight; high cost and difficult to process |

|

Aluminum Alloys |

5083, 6061 |

Air, fresh water |

-50°C to 150°C |

Lightweight, but low strength; unsuitable for high-pressure environments |

Cast iron (HT200, QT400-15) is cost-effective and easy to cast, but its limited strength and corrosion resistance make it suitable only for freshwater or low-pressure air pipelines. It is unsuitable for use in seawater or high-temperature, high-pressure environments. Carbon steels, such as WCB and WCC, are widely used in high-pressure fuel and lubricating oil systems due to their strength and thermal resistance. However, they are susceptible to electrochemical corrosion in seawater and therefore require protective surface treatments, such as galvanizing, spray coatings, or plastic linings. Stainless steels, such as 304, 316L, and duplex 2205, are preferred for corrosive systems. In particular, 316L provides excellent resistance to chlorides, while duplex 2205 offers high strength and superior pitting resistance, making it especially well-suited for high-pressure seawater valves. Copper alloys, including tin bronze (ZCuSnSPb5Zn5) and aluminum bronze (ZCuAl9Fe4Ni4Mn2), are widely used in seawater systems. Tin bronze is commonly used for the valve bodies and bonnets of low-pressure valves, whereas aluminum bronze—with its higher strength and superior erosion–corrosion resistance—is ideal for high-pressure, high-flow valves, such as those at seawater pump outlets. Nickel–aluminum bronze (C95800), which combines strength and corrosion resistance, is often used in high-speed flow control valves. For extreme environments, such as the ultra-low temperatures encountered in submersibles or LNG vessels, high-performance alloys—such as titanium (TA2, TAS) and nickel-based alloys (e.g., Inconel 625)—are essential. The selection of fastener materials must balance strength, corrosion resistance, and galvanic compatibility with the connected components. Table 2 summarizes typical choices.

Table 2. Material Selection for Marine Valve Fasteners

|

Fastener Type |

Common Materials |

Surface Treatment |

Applicable Environment |

|

Carbon Steel Bolts |

35CrMo, 42CrMo |

Galvanized, cadmium-plated |

General, non-seawater contact areas |

|

Stainless Steel |

A4-70 (304), A4-80 (316) |

Passivated |

Seawater, high-humidity environments |

|

Copper Alloys |

H62, QA19-4 |

None |

For use with copper alloy valves |

|

Titanium Alloys |

TA2, TAS |

Anodized |

Highly corrosive environments (e.g., LNG vessels) |

Stainless steel fasteners (A4-70, A4-80) are widely used for their corrosion resistance, whereas carbon steel fasteners must be galvanized or cadmium-plated for marine applications. Titanium bolts (TA2) provide superior corrosion resistance but are prone to thread galling, necessitating the use of an anti-seize agent (e.g., molybdenum disulfide) during assembly. For valve stems, strength, wear resistance, and corrosion resistance must all be considered. Stainless steels, such as 20Cr13 and 17-4PH, are commonly used for their well-balanced performance. For copper alloy valves, aluminum bronze (QA19-4) stems help reduce galvanic corrosion. Titanium alloy stems (TA2) offer excellent corrosion resistance but are expensive and difficult to machine, making them suitable only for specialized applications. To extend service life, valve stem surfaces are treated with hard chrome plating, nitriding, or wear-resistant coatings applied by spraying, to prevent seal failure caused by friction with the packing. Seal materials directly influence leakage rates and service life. Seals can be classified into three main types, as shown in Table 3.

Table 3. Material Selection for Marine Valve Seals

|

Seal Type |

Common Materials |

Applicable Conditions |

|

Gaskets |

Asbestos-rubber sheet, PTFE, spiral wound gaskets |

Medium- and low-pressure steam, fuel systems |

|

Rubbers |

NBR, FKM, EPDM |

Seawater, chemical media |

|

Packings |

Graphite braided packing, PTFE composite packing |

High-temperature, high-pressure valves (e.g., steam systems) |

In practice, the most common marine valve is the flanged cast steel globe valve, typically used under ambient temperature and pressure conditions. WCB cast steel is typically used for the body, 35CrMo galvanized carbon steel for the fasteners, and 20Cr13 stainless steel for the stem, with PTFE gaskets providing the seal.

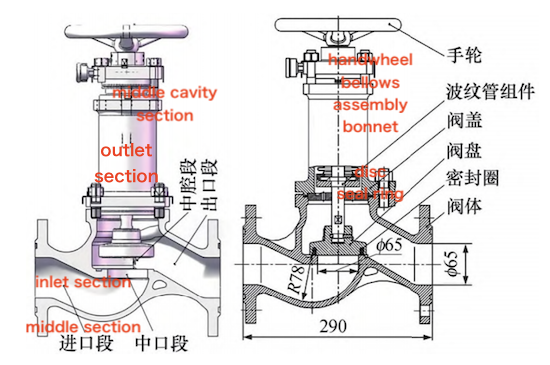

Due to the limited space on board ships, valve size and weight must be strictly controlled. Standardized interfaces and dimensions should be prioritized during design, with GB/T 11698 serving as a reference for determining structural length. Non-standard designs should be minimized. For underwater valves, a safety factor of at least 4.0 is typically required to ensure reliable performance under high-pressure conditions. Finite element analysis is employed to optimize pressure-bearing components, minimizing material usage while maintaining strength and achieving a lightweight design. Figure 1 shows a DN65 marine flanged cast steel globe valve. It features a typical lift-type design, with an S-shaped flow path inside the valve body. This configuration effectively controls the flow direction of the medium but also introduces significant localized resistance losses. The valve body has an inlet and outlet diameter of 65 mm, an overall length of 290 mm, and an internal surface roughness of 12.5 μm. The valve disc features a flat sealing structure with a surface roughness of 6.3 μm and an opening height of 18.5 mm, incorporating an internal PTFE seal to ensure optimal sealing performance and wear resistance. The handwheel is connected to the valve stem via a trapezoidal thread with a 1:4 transmission ratio, maintaining the operating torque within a reasonable range. The valve bonnet and body are connected by flanges and fastened with eight M16 bolts, evenly distributed in accordance with ASME B16.5 standards. The bolt preload torque is maintained between 120 and 150 N·m.

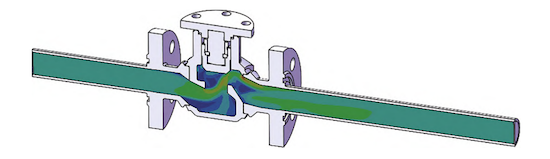

Fluid dynamics simulations were performed using ANSYS Fluent. The computational domain included an inlet section five times the pipe diameter and an outlet section ten times the pipe diameter. A structured meshing strategy was employed, with boundary layer grids generated near the wall region. The dimensionless wall distance (y*) was maintained between 30 and 50. The total number of cells in the global grid reached approximately 420,000. The model is illustrated in Figure 2.

Figure 1 DN65 marine flanged cast steel globe valve

Figure 2 Fluid dynamics simulation model

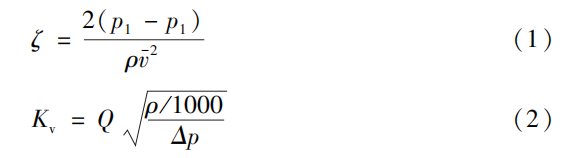

The turbulence was modeled using the Realizable k-ε model with enhanced wall treatment, and the convergence residual was set to 1 × 10⁻⁵. Five different flow conditions (42–70 m³/h) were evaluated. The inlet boundary condition was defined as a velocity inlet, while the outlet was specified as a pressure outlet at 101.325 kPa. The SIMPLE algorithm and second-order upwind discretization scheme were used for the calculations. By monitoring the pressure difference between the inlet and outlet, the flow resistance coefficient and the flow coefficient KKKwere determined using the following equations:

Where:

P1: Inlet pressure, Pa

P2: Outlet pressure, Pa

ρ: Fluid density, kg/m³

v: Flow velocity, m/s

Δp: Valve differential pressure, Pa

Q: Flow rate, m³/h

Experiments were conducted on a test platform compliant with ISO 5208, using an electromagnetic flowmeter and a differential pressure transmitter, both with an accuracy of 0.5%. The test medium was room-temperature water with a kinematic viscosity of 1.01 × 10⁻⁶ m²/s. Each test condition was repeated three times, and the average value was recorded. A comparison of the experimental results with the simulation data is presented in Table 4. The maximum deviation between the simulated and measured values did not exceed 3.1%, confirming the reliability of the numerical model.

Table 4 Experimental Verification Results

|

Flow rate (m³/h) |

Simulated Δp (kPa) |

Measured Δp (kPa) |

Error (%) |

Simulated Kv |

Measured Kv |

Error (%) |

|

42.0 |

33.38 |

34.12 |

2.17 |

72.70 |

71.85 |

1.18 |

|

48.0 |

43.53 |

44.87 |

2.99 |

72.75 |

71.62 |

1.58 |

|

54.3 |

55.62 |

57.31 |

2.95 |

72.81 |

71.38 |

2.00 |

|

61.3 |

69.65 |

71.84 |

3.05 |

73.45 |

71.92 |

2.13 |

|

70.0 |

91.61 |

94.28 |

2.82 |

73.14 |

71.56 |

2.21 |

The molding quality of the valve body blank directly affects the performance of the final product. The process control flow is shown in Figure 3. Resin sand molding or lost foam casting can produce a denser casting structure. For valve bodies with complex geometries, a well-designed gating and riser system can effectively reduce defects such as shrinkage cavities and air pockets. After casting, strict annealing or normalizing must be carried out to relieve internal stresses and enhance mechanical properties. Critical sections of the casting must also undergo radiographic or ultrasonic inspection to verify the absence of defects that could compromise structural integrity. The valve body sealing surface is typically machined by precision turning or grinding, with surface roughness maintained at Ra ≤ 0.8 μm and flatness deviation not exceeding 0.02 mm. As a critical moving component, the valve stem must maintain a circularity error of less than 0.01 mm. After grinding, the surface should be polished, and cutting parameters must be carefully selected to prevent deformation due to cutting heat. For difficult-to-machine materials, such as stainless steel, specialized tools and coolants must be used to ensure surface quality. All machined parts must undergo dimensional inspection, and critical mating dimensions should be accurately measured using pneumatic gauges or a coordinate measuring machine (CMM). The valve body and flange are welded using precision methods, such as argon arc welding or plasma welding. Grooves must be machined and cleaned prior to welding, and radiographic inspection is required afterward. All welders must be certified and follow approved welding procedures. In addition to visual inspection, critical welds must undergo penetrant or ultrasonic testing to ensure the absence of cracks, lack of fusion, or other defects. For martensitic stainless steel valve stems, quenching and tempering are required to achieve an optimal balance of hardness and toughness. Austenitic stainless steel components must undergo solution treatment to eliminate work hardening. After machining, all parts must be thoroughly cleaned to remove contaminants, such as cutting fluids and chips. For valves used in hydraulic systems, internal cleanliness must meet NAS1638 Class 6 or higher. Before assembly, all parts should be coated with rust-preventive oil to prevent corrosion during storage. During cleaning, dedicated equipment should be used, and cleaning fluids must be replaced regularly to prevent cross-contamination. Finally, parts should be wiped with a white cloth to ensure that no visible contaminants remain.

Assembly represents the final checkpoint for ensuring the quality of marine valves. Strict assembly procedures and quality control checkpoints must be implemented.

Pre-assembly

All parts must be thoroughly cleaned using a three-stage process (alkaline degreasing → ultrasonic cleaning → deionized water rinsing) to ensure that no chips or contaminants remain in the flow channels. A CMM should be used to recheck critical dimensions. The valve stem straightness deviation must not exceed 0.01 mm, and the sealing surface flatness must be within 0.02 mm. The material certificates for O-rings and packing must be checked to verify that their media resistance meets the required specifications.

Assembly

A guide tool should be used when installing the valve stem to prevent damage to the stuffing box wall. Packing compression is carried out in three stages (30% → 70% → 100% of the design compression force), with each layer of packing rings staggered by 120°. Before installing the bellows assembly, an airtightness test (0.6 MPa for 3 minutes) must be conducted. During assembly, compression should be controlled within ±5% of the standard stroke. Bearings should be assembled using induction heating (temperature controlled at 125 ± 5 °C), and runout must be measured immediately after installation, with allowable values ranging from 0.03 to 0.08 mm. Bolts are tightened using a stepwise cross-pattern method: first pre-tightened to 50% of the design load, then fully tightened to 100%.

Post-assembly

A manual operation test must confirm that the opening and closing torque does not exceed 120% of the design value. A helium mass spectrometer is used to inspect static sealing points, ensuring a leakage rate of ≤ 1 × 10⁻⁹ Pa·m³/s. Pressure testing is conducted using an automatic recording system. The shell test pressure is set to 1.5 times the working pressure, with a holding time of at least 10 minutes. Nameplate information must be verified against the actual product, including material identification and pressure rating. Before packaging, all external surfaces should be coated with vapor-phase corrosion inhibitors (VCI/VCPI), and special protective covers must be installed on the flange surfaces. By applying the full-process quality control method proposed in this study, the valves achieved a 10% reduction in weight, zero leakage, and a 10% increase in service life.

The reliability of marine engineering equipment is crucial for both ship safety and the sustainable development of marine resources. This study systematically examined a full-process quality control method for marine valves, with a focus on material selection, structural design, processing technology, and assembly testing. In terms of materials, the corrosion resistance of metals in marine environments was assessed. Structural design was evaluated through numerical simulations of flow capacity. For processing, precision machining and surface treatment standards were implemented, while in assembly, strict inspection and acceptance procedures were enforced. The results demonstrate that implementing full-process quality control significantly enhances valve sealing performance and durability, extends service life, and improves adaptability to harsh marine conditions. Future research should focus on intelligent testing technologies, the development of advanced corrosion-resistant materials, and full-lifecycle quality traceability to further enhance the global competitiveness of China’s marine valves.