Surface crack defects have a great influence on the quality of stainless steel seamless pipe in the manufacturing process and the use safety after delivery, which is an unacceptable defect. Therefore, it is necessary to analyze the macroscopic characteristics of the surface cracks of stainless steel seamless pipes, find out the causes of cracks and put forward improvement measures.

Macroscopic characteristics of steel pipe surface cracks

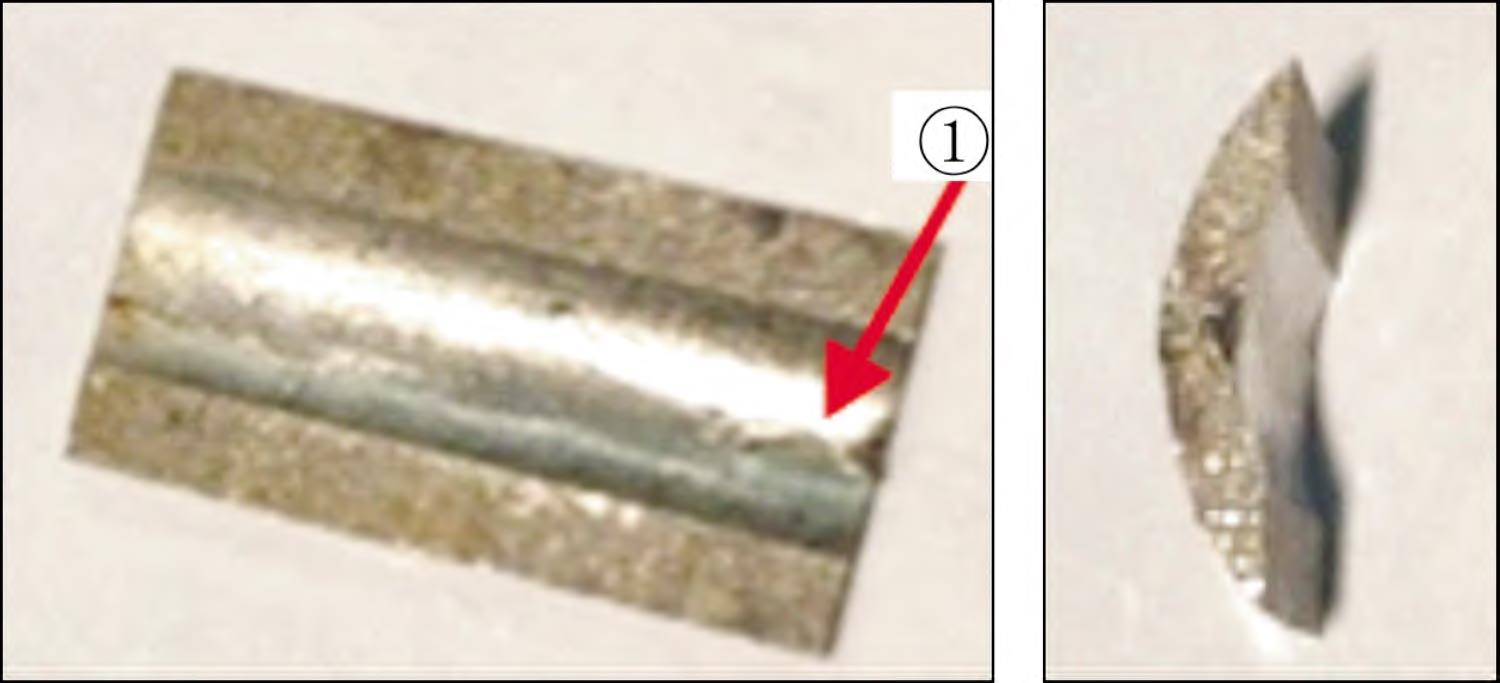

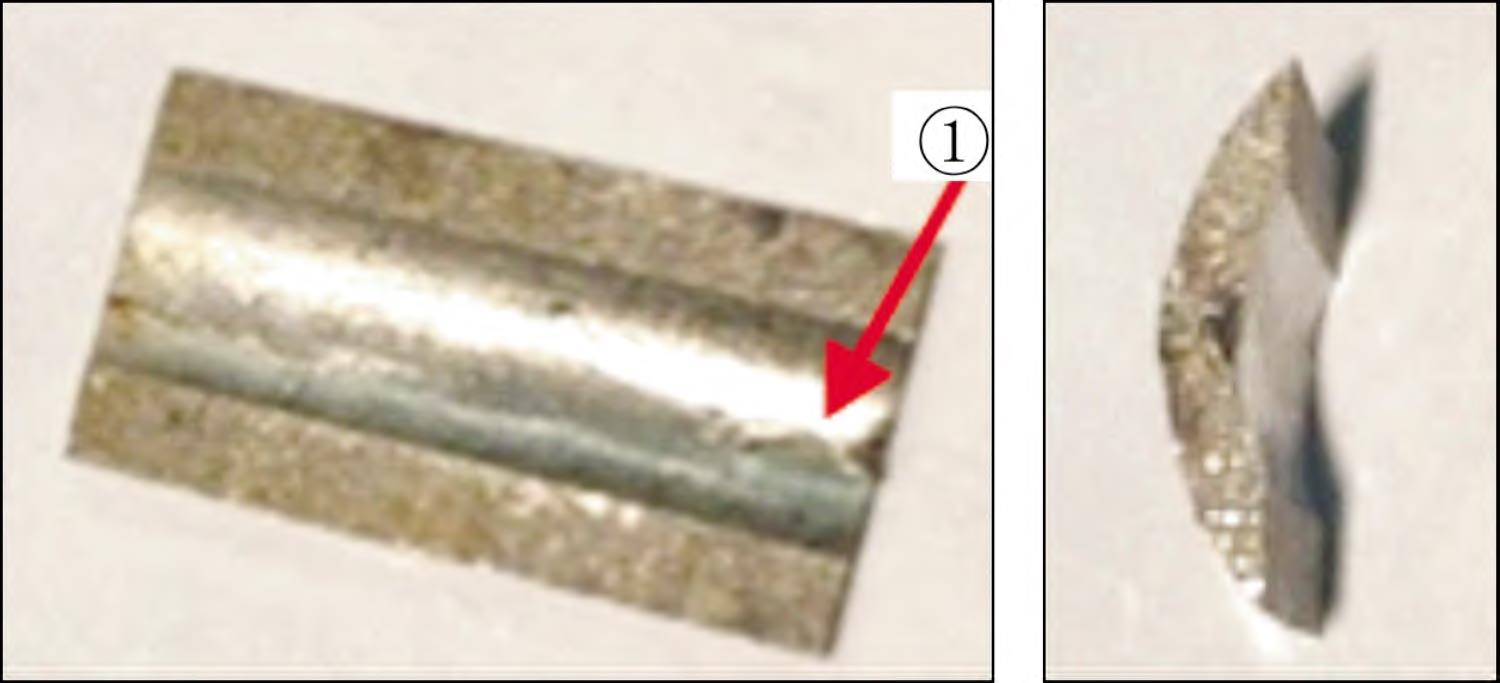

Taking 0Cr18Ni9 stainless steel seamless pipe with φ 10mm× 1mm specification as an example, the process route is as follows: round steel piercing → pickling → grinding → cold rolling of intermediate products → deoiling → heat treatment (solid solution) in natural gas furnace → pickling → grinding → cold rolling of finished products → deoiling → bright heat treatment (solid solution) of finished products → straightening → pipe cutting to length and inspection of finished products. The stainless steel seamless pipe had a leak during the airtightness test of the finished product. The visual inspection found that there was a longitudinal defect on the outer surface, which was suspected to be a crack through the wall thickness direction. After anatomical observation, there is indeed a crack at the corresponding position, and the cross-section can be seen through, as shown in Figure 1.

Fig. 1 the macroscopic inner wall and cross-section of stainless steel seamless pipe after dissection

Physical and chemical analysis

Samples were taken from unqualified φ 10mm× 1mm stainless steel seamless pipes with leakage during an air tightness test, and physical and chemical analysis was carried out.

1. Chemical composition inspection

The chemical composition of the sample was analyzed according to GB/T 11170—2016 《 Determination of Multi-element Content in Stainless Steel 》, and the results are shown in Table 1. After comparison, its composition meets the requirements of 0Cr18Ni9 material specified in GB/T 14976—2002 "Seamless Stainless Steel Pipe for Fluid Transport", and there is no obvious abnormality in the main composition of the matrix.

2. Analysis of mechanical properties at room temperature

(1) Tensile properties. According to GB/T 228.1—2010 "Tensile Test of Metallic Materials Part 1: Room Temperature Test Methods", the room temperature tensile test is carried out. The results are shown in Table 2. It is found that the strength and plasticity of the φ 10mm× 1mm stainless steel seamless pipe are better than the requirements of GB/T14976 standard.

Table 1 Chemical composition (mass fraction) of φ 10mm× 1mm stainless steel seamless pipe

Table 2 Mechanical properties of stainless steel seamless pipe with φ 10mm× 1mm specification at room temperature

(2) Flaring and flattening test. According to GB/T 242—2007 "Flaring Test Method for Metal Tubes" and GB/T 246—2017 "Flashing Test Method for Metal Tubes", the flaring and flattening tests were carried out. A conical jacking core with a jacking angle of 60 is selected, the outer diameter flaring rate is 10%, and there is no crack or crack in the pipe wall after flaring; At the same time, after flattening test, there are no cracks or cracks in the inner and outer walls of steel pipes.

3. intergranular corrosion performance test

According to GB/T 4334—2020 "Test Method for Corrosion of Austenite and Ferrite-Austenite (Dual-phase) Stainless Steel" E, the copper-copper sulfate -16% sulfuric acid corrosion test was carried out. After bending 180, there was no intergranular corrosion crack on the surface of the sample.

4. Metallographic analysis

The defects were cut and inlaid by wire cutting, polished and electrolyzed by 10% oxalic acid solution, then cleaned by ultrasonic wave, and observed under a metallographic microscope. The crack obliquely runs through the wall thickness at an angle of 45 with the pipe wall; There is a bifurcation in the middle of the crack, the crack width in the inner direction of the pipe wall is wider than that in the outer direction, and the crack bottom at the inner side is obviously folded. Carburizing and fine grain appeared in the grain near the middle of the crack, and the bifurcation was obvious. Judging from the crack shape, the crack has undergone secondary propagation. Take a longitudinal sample near the defects of the pipe body (position ① in Figure 1), observe its metallographic structure, and rate the nonmetallic inclusions according to method A of GB/T 10561—2005 Standard Rating Chart Microscopic Inspection Method for the Content of Nonmetallic Inclusions in Steel. In the microstructure, except for Class B and Class D fine inclusions, which are 1.0 and 0.5 respectively, the rest are 0. It can be seen that the content of nonmetallic inclusions in the matrix area is normal.

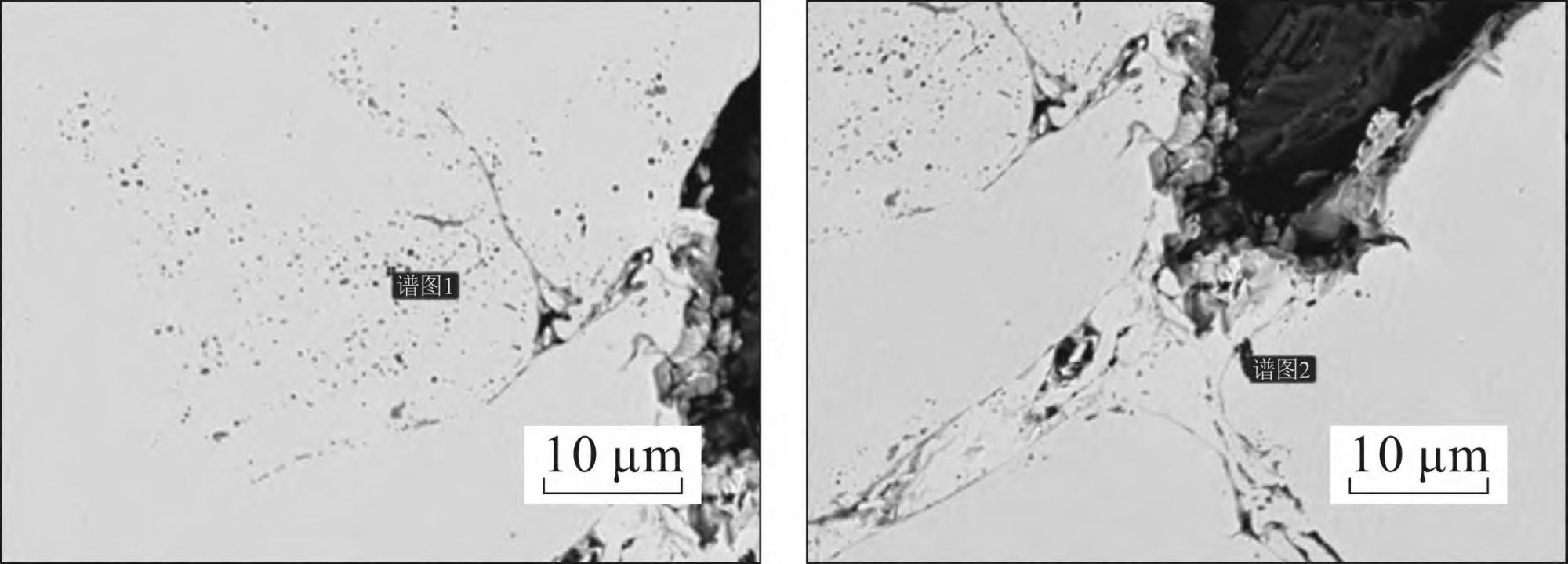

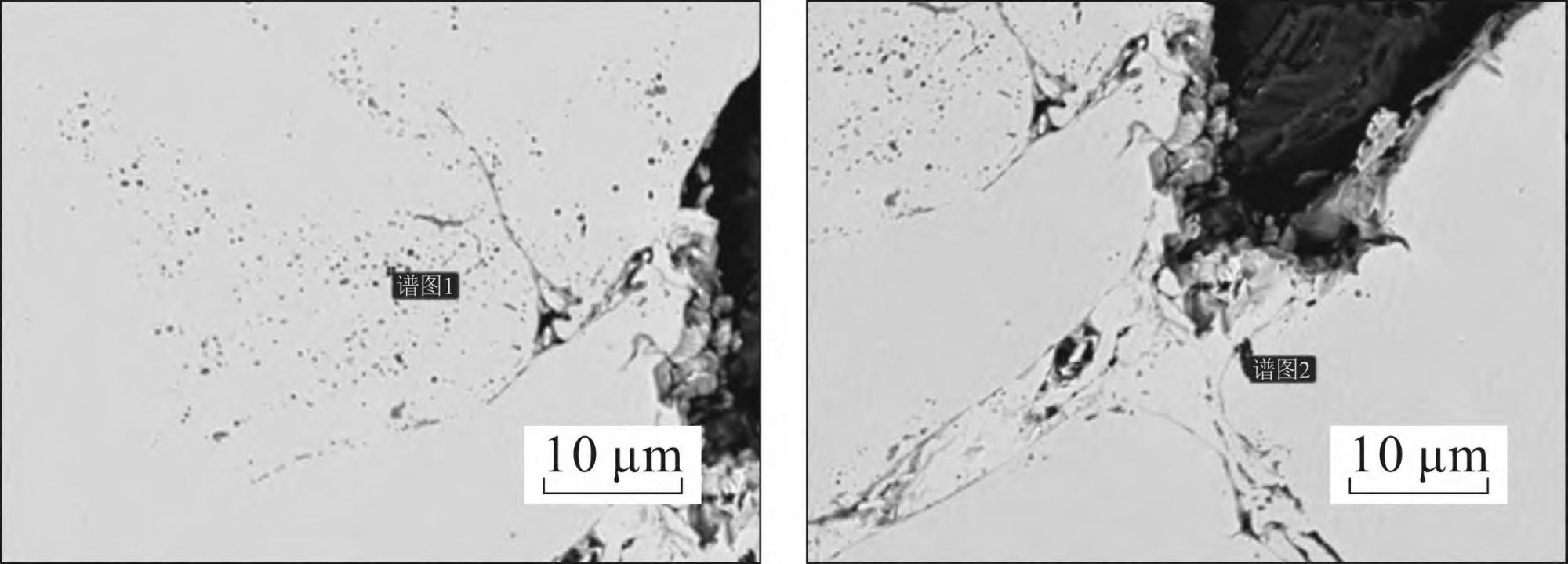

5. Scanning electron microscope analysis

Scanning electron microscope analysis shows that there are a large number of points and block suspected inclusions in the defect. Some points were selected for energy spectrum analysis of the suspected inclusion. The defect morphology under a scanning electron microscope is shown in Figure 2, and the energy spectrum analysis results are shown in Table 3. Compared with the matrix composition, the contents of Si and Al in the above two points are abnormally high, so it can be judged that there are silicon oxide and aluminum oxide inclusions in these two points.

(a) Morphology 1

(b) Morphology 2

Fig. 2 Defect morphology of stainless steel seamless pipe under a scanning electron microscope

Table 3 Energy spectrum analysis results (mass fraction) of stainless steel seamless pipe defects

Cause analysis of crack

By observing the crack morphology, it is found that the crack extends obliquely at an angle of 45 with the inner wall. Because the pipe itself has good mechanical properties and high ductility, it can be ruled out that it is rolled and folded due to cold rolling. The width of the crack develops from coarse to fine, and bifurcation occurs in the middle, which indicates that through the crack is not formed at one time. In the cold rolling process, the steel pipe is subjected to three-dimensional compressive stress, and the wall thickness direction is mainly deformed and extended by two-dimensional compressive stress and two-dimensional frictional resistance. The original crack expands under the stress, and the crack bottom is irregular, so it is easy to form bifurcation, and the expanded crack is thinner than the original defect. By analyzing the microstructure near the crack, it is found that there is a fine grain layer at the bifurcation. The reasons for this phenomenon are: there are crack defects in the pipe before cold rolling, rolling oil enters the crack during cold rolling, and the rolling oil in the crack gap can not be completely cleaned when oil is removed, while the rolling oil and degreasing agent is rich in organic matters, and the rolling oil remaining in the crack is carburized after heat treatment. The higher the carbon content in steel, the higher the nucleation rate, resulting in the formation of a fine crystal layer. Therefore, this defect has already appeared in the previous pass, rather than the finished product or the finished product after cold rolling. From the analysis of SEM results, it can be judged that there are concentrated alumina and silica inclusions in the local area of the sample. Such inclusions generally come from smelting or casting, resulting in defects in round steel. In the subsequent piercing and cold rolling deformation process, they are affected by pressure processing, thus forming cracks and penetrating through the wall thickness, resulting in leakage during the air tightness test. Therefore, the penetrating crack exists in the original tube blank itself, rather than being expanded and cracked by pressure during the air tightness test.

Improvement measures

By making reasonable measures to control the cracks in the production process of stainless steel seamless pipes, the quality of products can be further improved.

(1) Acceptance of raw materials. For small-diameter stainless steel, the technical conditions for purchasing special tube blanks are formulated, and the included content and external surface quality are quantified in detail. During the reinspection of raw materials, it is important to check the inclusion level to prevent defects when processed into finished products.

(2) Strengthen the grinding of waste pipes. Strengthen visual inspection, mark the defects found, and isolate the defective steel pipes; With the aid of visual inspection such as an endoscope, the defects on the inner wall of the steel pipe are located, and then the defects are polished by fixed-point grinding.

(3) Increase nondestructive testing. Formulate reasonable acceptance criteria, carry out ultrasonic flaw detection on steel pipes before cold rolling, mark and isolate the defective steel pipes, and grind them at fixed points to eliminate defects.

(4) Re-inspect the above-mentioned fixed-point ground steel pipes with the same detection method, and put them into production if they are qualified, so as to avoid unqualified products flowing into the next working procedure.

Conclusion

There was a leak in the seamless stainless steel pipe of φ 10mm× 1mm made of 0Cr18Ni9 material during the airtightness test of the finished product, and it was found that there was a crack on the outer surface running through the wall thickness direction. According to the analysis, there are inclusions in the perforated tube blank, and cracks are formed during the piercing process, but the defects are not removed in the subsequent production process, which leads to the further expansion of the cracks in the cold rolling process and finally penetrates the tube wall.

Macroscopic characteristics of steel pipe surface cracks

Taking 0Cr18Ni9 stainless steel seamless pipe with φ 10mm× 1mm specification as an example, the process route is as follows: round steel piercing → pickling → grinding → cold rolling of intermediate products → deoiling → heat treatment (solid solution) in natural gas furnace → pickling → grinding → cold rolling of finished products → deoiling → bright heat treatment (solid solution) of finished products → straightening → pipe cutting to length and inspection of finished products. The stainless steel seamless pipe had a leak during the airtightness test of the finished product. The visual inspection found that there was a longitudinal defect on the outer surface, which was suspected to be a crack through the wall thickness direction. After anatomical observation, there is indeed a crack at the corresponding position, and the cross-section can be seen through, as shown in Figure 1.

Fig. 1 the macroscopic inner wall and cross-section of stainless steel seamless pipe after dissection

Physical and chemical analysis

Samples were taken from unqualified φ 10mm× 1mm stainless steel seamless pipes with leakage during an air tightness test, and physical and chemical analysis was carried out.

1. Chemical composition inspection

The chemical composition of the sample was analyzed according to GB/T 11170—2016 《 Determination of Multi-element Content in Stainless Steel 》, and the results are shown in Table 1. After comparison, its composition meets the requirements of 0Cr18Ni9 material specified in GB/T 14976—2002 "Seamless Stainless Steel Pipe for Fluid Transport", and there is no obvious abnormality in the main composition of the matrix.

2. Analysis of mechanical properties at room temperature

(1) Tensile properties. According to GB/T 228.1—2010 "Tensile Test of Metallic Materials Part 1: Room Temperature Test Methods", the room temperature tensile test is carried out. The results are shown in Table 2. It is found that the strength and plasticity of the φ 10mm× 1mm stainless steel seamless pipe are better than the requirements of GB/T14976 standard.

| project | C | Si | Mn | P | S | Cr | Ni | Al |

| measured value | 0.02 | 0.48 | 1.75 | 0.031 | 0.011 | 18.51 | 8.92 | 0.002 5 |

| GB/T 14976 requirement |

≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 18.00~20.00 | 8.00~11.00 |

| project | tensile strength | Rm/MPa | yield strength | Rp0.2 /MPa | extensibility | A/% |

| 1 | 2 | 1 | 2 | 1 | 2 | |

| measured value | 707 | 705 | 220 | 243 | 61 | 63 |

| GB/T 14976 | ≥520 | ≥205 | ≥35 | |||

(2) Flaring and flattening test. According to GB/T 242—2007 "Flaring Test Method for Metal Tubes" and GB/T 246—2017 "Flashing Test Method for Metal Tubes", the flaring and flattening tests were carried out. A conical jacking core with a jacking angle of 60 is selected, the outer diameter flaring rate is 10%, and there is no crack or crack in the pipe wall after flaring; At the same time, after flattening test, there are no cracks or cracks in the inner and outer walls of steel pipes.

3. intergranular corrosion performance test

According to GB/T 4334—2020 "Test Method for Corrosion of Austenite and Ferrite-Austenite (Dual-phase) Stainless Steel" E, the copper-copper sulfate -16% sulfuric acid corrosion test was carried out. After bending 180, there was no intergranular corrosion crack on the surface of the sample.

4. Metallographic analysis

The defects were cut and inlaid by wire cutting, polished and electrolyzed by 10% oxalic acid solution, then cleaned by ultrasonic wave, and observed under a metallographic microscope. The crack obliquely runs through the wall thickness at an angle of 45 with the pipe wall; There is a bifurcation in the middle of the crack, the crack width in the inner direction of the pipe wall is wider than that in the outer direction, and the crack bottom at the inner side is obviously folded. Carburizing and fine grain appeared in the grain near the middle of the crack, and the bifurcation was obvious. Judging from the crack shape, the crack has undergone secondary propagation. Take a longitudinal sample near the defects of the pipe body (position ① in Figure 1), observe its metallographic structure, and rate the nonmetallic inclusions according to method A of GB/T 10561—2005 Standard Rating Chart Microscopic Inspection Method for the Content of Nonmetallic Inclusions in Steel. In the microstructure, except for Class B and Class D fine inclusions, which are 1.0 and 0.5 respectively, the rest are 0. It can be seen that the content of nonmetallic inclusions in the matrix area is normal.

5. Scanning electron microscope analysis

Scanning electron microscope analysis shows that there are a large number of points and block suspected inclusions in the defect. Some points were selected for energy spectrum analysis of the suspected inclusion. The defect morphology under a scanning electron microscope is shown in Figure 2, and the energy spectrum analysis results are shown in Table 3. Compared with the matrix composition, the contents of Si and Al in the above two points are abnormally high, so it can be judged that there are silicon oxide and aluminum oxide inclusions in these two points.

(a) Morphology 1

(b) Morphology 2

Fig. 2 Defect morphology of stainless steel seamless pipe under a scanning electron microscope

Table 3 Energy spectrum analysis results (mass fraction) of stainless steel seamless pipe defects

| position | C | O | Al | Na | Si | V | Cr | Mn | Fe | Ni |

| Illustration 1 | 5.14 | 20.56 | - | 1.84 | 3.12 | 0.23 | 22.65 | 8.73 | 33.61 | 4.13 |

| Illustration 2 | 13.19 | 38.37 | 29.48 | - | 0.13 | - | 3.82 | 0.38 | 12.88 | 1.57 |

Cause analysis of crack

By observing the crack morphology, it is found that the crack extends obliquely at an angle of 45 with the inner wall. Because the pipe itself has good mechanical properties and high ductility, it can be ruled out that it is rolled and folded due to cold rolling. The width of the crack develops from coarse to fine, and bifurcation occurs in the middle, which indicates that through the crack is not formed at one time. In the cold rolling process, the steel pipe is subjected to three-dimensional compressive stress, and the wall thickness direction is mainly deformed and extended by two-dimensional compressive stress and two-dimensional frictional resistance. The original crack expands under the stress, and the crack bottom is irregular, so it is easy to form bifurcation, and the expanded crack is thinner than the original defect. By analyzing the microstructure near the crack, it is found that there is a fine grain layer at the bifurcation. The reasons for this phenomenon are: there are crack defects in the pipe before cold rolling, rolling oil enters the crack during cold rolling, and the rolling oil in the crack gap can not be completely cleaned when oil is removed, while the rolling oil and degreasing agent is rich in organic matters, and the rolling oil remaining in the crack is carburized after heat treatment. The higher the carbon content in steel, the higher the nucleation rate, resulting in the formation of a fine crystal layer. Therefore, this defect has already appeared in the previous pass, rather than the finished product or the finished product after cold rolling. From the analysis of SEM results, it can be judged that there are concentrated alumina and silica inclusions in the local area of the sample. Such inclusions generally come from smelting or casting, resulting in defects in round steel. In the subsequent piercing and cold rolling deformation process, they are affected by pressure processing, thus forming cracks and penetrating through the wall thickness, resulting in leakage during the air tightness test. Therefore, the penetrating crack exists in the original tube blank itself, rather than being expanded and cracked by pressure during the air tightness test.

Improvement measures

By making reasonable measures to control the cracks in the production process of stainless steel seamless pipes, the quality of products can be further improved.

(1) Acceptance of raw materials. For small-diameter stainless steel, the technical conditions for purchasing special tube blanks are formulated, and the included content and external surface quality are quantified in detail. During the reinspection of raw materials, it is important to check the inclusion level to prevent defects when processed into finished products.

(2) Strengthen the grinding of waste pipes. Strengthen visual inspection, mark the defects found, and isolate the defective steel pipes; With the aid of visual inspection such as an endoscope, the defects on the inner wall of the steel pipe are located, and then the defects are polished by fixed-point grinding.

(3) Increase nondestructive testing. Formulate reasonable acceptance criteria, carry out ultrasonic flaw detection on steel pipes before cold rolling, mark and isolate the defective steel pipes, and grind them at fixed points to eliminate defects.

(4) Re-inspect the above-mentioned fixed-point ground steel pipes with the same detection method, and put them into production if they are qualified, so as to avoid unqualified products flowing into the next working procedure.

Conclusion

There was a leak in the seamless stainless steel pipe of φ 10mm× 1mm made of 0Cr18Ni9 material during the airtightness test of the finished product, and it was found that there was a crack on the outer surface running through the wall thickness direction. According to the analysis, there are inclusions in the perforated tube blank, and cracks are formed during the piercing process, but the defects are not removed in the subsequent production process, which leads to the further expansion of the cracks in the cold rolling process and finally penetrates the tube wall.