In modern industrial piping systems, valves, as key components for controlling fluid flow, play an important role in regulating, diverting, and switching flow directions. Among them, three-way ball valves, with their unique three-port design and flexible flow control capabilities, have become an ideal choice widely applied in chemical, petroleum, HVAC, and water supply and drainage fields. Compared with traditional two-way valves, three-way ball valves can not only achieve multi-path fluid switching and distribution but also feature simple operation, excellent sealing performance, and strong corrosion resistance. This article will provide a comprehensive analysis from the aspects of the basic structure, working principle, characteristics, classification, applications, and maintenance of three-way ball valves, helping readers gain an in-depth understanding of the design and application value of this multifunctional fluid control device.

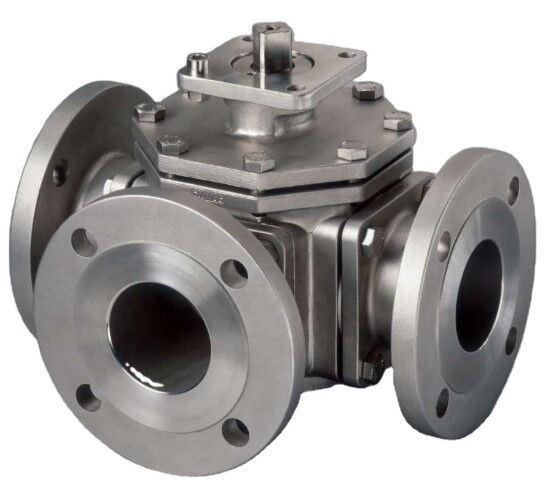

A three-way ball valve is a valve with three ports, and its core component is a ball, which has a passage that controls the direction of fluid flow by rotating the ball. A three-way ball valve mainly consists of the following parts.

- Ball: The ball is the core component of a three-way ball valve and is usually made of high-strength, corrosion-resistant materials such as stainless steel, copper alloy, or titanium alloy. The ball has one or two passages, which can close or open the corresponding pipelines to control fluid flow. The surface of the ball is precisely machined to ensure a tight fit with the valve seat, achieving good sealing performance.

- Valve Seat: The valve seat is located at the three outlets of the ball and is usually made of materials with excellent sealing performance and corrosion resistance, such as PTFE. The function of the valve seat is to seal the fluid and prevent leakage. The valve seat fits tightly with the ball and further enhances sealing through sealing rings.

- Sealing Ring: The sealing ring is usually located between the ball and the valve seat to enhance the sealing effect. Common sealing ring materials include rubber and PTFE. The design and material selection of the sealing ring are crucial to the sealing performance of the three-way ball valve, effectively preventing fluid leakage and ensuring reliable valve operation.

- Stem and Handle: The stem usually connects the handle and the ball to control the rotation of the ball. The handle is the component used to open or close the three-way ball valve and is usually located on top of the ball. By rotating the handle, the ball can be turned to control the direction of fluid flow. In some automated systems, the handle can be replaced by electric or pneumatic actuators for remote control.

The working principle of a three-way ball valve is relatively simple but highly efficient. Its valve body has three ports, either one inlet and two outlets or two inlets and one outlet. Unlike ordinary valves, different positions of the internal valve core (ball) connect different outlets. For example, when the valve core is in the lower position, the left and right sides connect while the bottom outlet is closed; when the valve core is in the upper position, the left and bottom sides connect while the right outlet is closed.

- Manual Operation: For manual three-way ball valves, operators can control the rotation of the ball by turning the handle. The handle usually rotates 90° or 180° to achieve different fluid flow directions. This operation is simple and intuitive, suitable for scenarios requiring manual control.

- Pneumatic Operation: The working principle of pneumatic three-way ball valves is slightly more complex. When the pneumatic three-way ball valve opens, air enters two ports and exhausts through four, pushing two pistons to move outward, compressing springs, and rotating the output shaft counterclockwise. When closing, due to air loss or power failure, the springs push the two pistons inward and toward the center, rotating the output shaft clockwise. This pneumatic operation allows fast and accurate control, suitable for automated control scenarios.

Three-way ball valves have many unique features that make them stand out in the field of fluid control.

- Simple Structure and Compact Size: Three-way ball valves adopt an integrated structure with four-seat sealing, minimal flange connections, high reliability, and compact design. This compact structure allows them to occupy minimal space, making them especially suitable for installation in tight spaces or at pipeline connections.

- Easy Operation: Operation of three-way ball valves is very simple, requiring only rotation of the handle or an electric device to open, close, or adjust flow. This straightforward operation makes them very convenient in practical applications without complex procedures.

- Excellent Sealing Performance: Three-way ball valves provide excellent sealing. The ball and valve seat, with the help of sealing rings, achieve tight sealing, effectively preventing fluid leakage. This reliable sealing allows the valve to maintain stable operation under various conditions.

- Strong Corrosion Resistance: The ball and valve seat are typically made of corrosion-resistant materials such as stainless steel, copper alloy, titanium alloy, and PTFE. These materials meet the flow control needs of various media including liquids, gases, steam, and oils, allowing three-way ball valves to operate stably in corrosive chemical and petrochemical environments.

- Excellent Flow Control: Three-way ball valves have good regulating performance, enabling precise control of flow and pressure to meet different process requirements. By rotating the ball, the connection or disconnection between the inlet and outlet or between the inlet and bypass can be achieved, thereby adjusting flow or switching flow direction.

- Long Service Life: The long service life of three-way ball valves mainly results from their structural design and material selection. The simple channel structure of the ball, minimal seal wear, and low opening torque reduce actuator specifications, ensuring reliable performance over long-term operation.

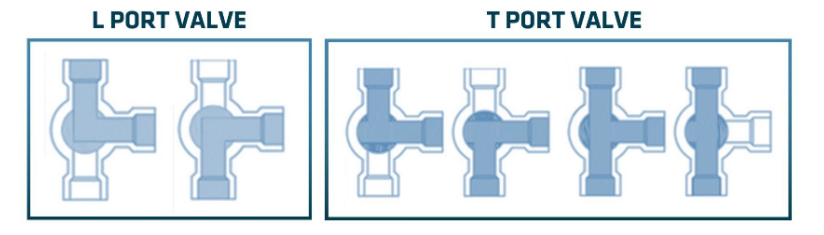

Three-way ball valves can be divided into different types based on their structure and function, mainly including L-type and T-type.

- L-Type: L-type three-way ball valves can only connect two perpendicular pipelines and cannot keep the third pipeline connected simultaneously. This type is suitable for switching flow between two pipelines, such as controlling supply and drainage in water systems.

- T-Type: T-type three-way ball valves can connect three perpendicular pipelines, cutting off the third port, and serve the purpose of diversion and merging. This type offers higher flexibility, suitable for mixing or distributing different media, such as controlling flow ratios or distribution in chemical production processes.

The multifunctionality and superior performance of three-way ball valves make them widely applied in multiple fields.

- Chemical Industry: During chemical production, it is necessary to mix different media or divert mixed media to different processing units. Three-way ball valves can adjust the ball position to easily achieve different mixing ratios or flow distribution. For example, in ammonia synthesis, three-way ball valves control the hydrogen-to-nitrogen ratio to ensure smooth reactions.

- HVAC Systems: In HVAC systems, three-way ball valves are used to distribute hot and cold water. During cooling or heating, the flow direction and ratio must be controlled to achieve precise temperature regulation. By adjusting the ball position, three-way ball valves flexibly control the flow direction and ratio of hot and cold water to meet the needs of different zones.

- Petroleum and Petrochemical Industry: In the petroleum and petrochemical industries, three-way ball valves control the diversion or mixing of crude oil, natural gas, and liquefied gas. For example, in refining, they manage different fractions to ensure smooth processing. They are also used in gas transportation and distribution to ensure safe and efficient delivery.

- Water Supply and Drainage Systems: In water supply and drainage systems, three-way ball valves control the switching of supply and drainage. In municipal systems, they may control the switch between firefighting and domestic water to ensure normal operation. They are also applied in wastewater treatment to control flow switching between treatment units.

To ensure long-term stable operation, three-way ball valves require regular maintenance.

- Regular Inspection: Regularly check the sealing performance and operational flexibility of the valve. Inspect the wear of sealing rings, seat stability, and ball rotation. Replace or repair faulty components promptly.

- Cleaning and Lubrication: Regularly clean the surface and internal parts of the valve to remove dust and debris. Lubricate stems, handles, and other components to maintain operational flexibility. Use appropriate lubricants and avoid excessive or unsuitable types that could affect sealing.

- Avoid Over-Operation: Avoid excessive force, especially in manual operation. Over-operation can damage the ball or seat, affecting sealing performance and service life.

- Consider Media Characteristics: Pay attention to the characteristics of the fluid. Using inappropriate media, especially corrosive or containing impurities, may negatively impact sealing performance and service life. In such cases, use corrosion-resistant materials or protective measures.

As a powerful and versatile fluid control device, the three-way ball valve, with its simple structure, easy operation, excellent sealing, strong corrosion resistance, and superior flow control, has been widely applied in chemical, petrochemical, HVAC, water supply and drainage, and wastewater treatment fields. Through this article, readers can gain a comprehensive understanding of three-way ball valves. Whether in industrial production or daily life, three-way ball valves play an important role, providing reliable solutions for fluid control. In the future, they will continue to support development across various fields with excellent performance and continuous technological innovation.