In our daily lives, bolts may seem insignificant, yet they play a crucial role in various mechanical and construction structures. From automobile engines to large bridges, the strength of bolts is directly related to the safety and reliability of structures. Therefore, understanding bolt strength grades and their importance is knowledge that every engineer, technician, and even ordinary user should master. This article will introduce relevant knowledge of bolt strength grades in detail to help you better select and use bolts.

Bolt strength refers to the ability of a bolt to resist failure when subjected to external forces. It mainly includes the following aspects:

Tensile strength is the maximum capacity of a bolt to resist fracture. Simply put, it is the maximum force that a bolt can withstand before breaking when being pulled.

For example, a bolt with a tensile strength of 800 MPa means that it will break only when subjected to a tensile force of 800 newtons per square millimeter.

Yield strength is the stress value at which a bolt begins to undergo obvious plastic deformation. When the force acting on the bolt reaches the yield strength, irreversible deformation will begin.

For example, a bolt with a yield strength of 640 MPa will start to deform when subjected to a force of 640 newtons per square millimeter, and it will not fully return to its original shape even after unloading.

Fatigue strength reflects the reliability of a bolt under long-term repeated loading. In practical applications, many bolts are subjected to cyclic loads, such as bolts in automobile engines. Bolts with high fatigue strength can maintain their performance after repeated loading and are not prone to fracture.

Different application scenarios impose different requirements on bolt strength. Through strength classification, bolts can be ensured to possess appropriate mechanical properties under corresponding conditions. This classification not only facilitates global procurement, use, and management of bolts, but also ensures that bolts of the same performance grade have consistent mechanical properties.

During design and manufacturing, ensuring that bolts meet specific mechanical performance requirements is critical. If bolt strength is insufficient, structural failure may occur, leading to safety accidents and property losses.

For example, in bridge construction, the use of bolts with insufficient strength may result in unstable bridge structures or even collapse.

Selecting appropriate bolt grades based on actual requirements can meet strength needs while reducing costs.

For example, in some ordinary mechanical connections, using high-strength bolts may be wasteful. Conversely, in high-load structural connections, using low-strength bolts cannot meet performance requirements.

Bolt strength grades are mainly affected by the following factors:

Carbon content and alloying elements such as manganese (Mn), chromium (Cr), and molybdenum (Mo) have a significant influence on bolt hardness, strength, and toughness.

For example, low-carbon steel bolts generally have lower strength but better toughness, while alloy steel bolts exhibit higher strength and hardness.

Forging, cold heading, thread rolling, and machining accuracy are critical for refining metal grain structure, reducing defects, and ensuring that the expected preload is achieved during assembly.

For example, finely processed bolts have fewer surface defects and finer grains, thereby improving overall bolt strength.

Quenching and tempering are key steps in improving bolt strength. By adjusting hardness and increasing toughness, brittle fracture can be prevented.

Normalizing and annealing are used to improve internal microstructure and eliminate residual stresses.

For example, bolts that have undergone quenching and tempering exhibit significantly improved strength and toughness.

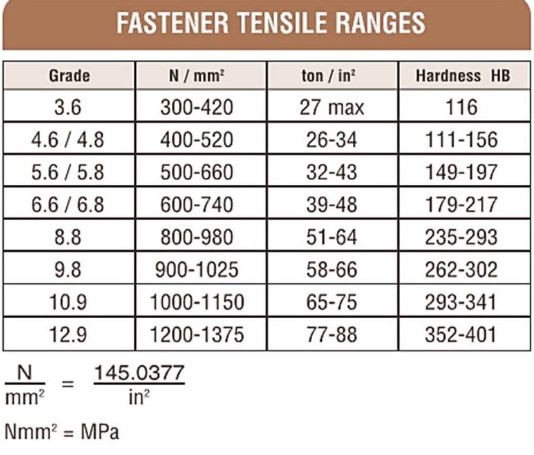

Bolt strength grades are classified based on the hardness, tensile strength, and yield strength of the bolt material. Different products and application scenarios require bolts of corresponding strength grades. Bolt strength grades are divided into standard grades and high-strength grades.

Standard-grade bolts usually refer to grade 4.6 and grade 4.8 bolts. These bolts have relatively low strength and are suitable for general mechanical connections.

For example, a grade 4.6 bolt has a tensile strength of 400 MPa and a yield strength of 240 MPa, and is typically made of low-carbon steel.

High-strength bolts refer to bolts of grade 8.8 and above, including grade 10.9 and grade 12.9. These bolts have higher strength and are suitable for structural connections subjected to higher loads.

For example, a grade 10.9 bolt has a tensile strength of 1000 MPa and a yield strength of 900 MPa, and is usually made of alloy steel.

Bolt performance grade designations consist of two numbers, representing the nominal tensile strength value of the bolt material and the yield ratio, respectively.

For example, a grade 4.6 bolt means that the nominal tensile strength of the bolt material reaches 400 MPa, and the yield ratio is 0.6, resulting in a yield strength of 240 MPa.

Selecting an appropriate bolt strength grade is critical. Different service conditions and load requirements require bolts of different grades. The following are some common application scenarios and corresponding bolt selection recommendations:

When bolts are subjected to static loads, the appropriate strength grade can be selected based on the required clamping force of the connection.

For example, in ordinary mechanical connections, grade 4.6 or grade 5.6 bolts are usually sufficient.

When bolts are subjected to dynamic loads, high-strength bolts should be selected and anti-loosening measures should be adopted.

For example, in automobile engines, grade 8.8 or grade 10.9 bolts are commonly used to ensure connection reliability.

If the connected components have high hardness, high-strength bolts should be selected; if the connected components are relatively soft, bolts with relatively lower strength grades can be used.

For example, when connecting high-strength steel components, grade 10.9 or grade 12.9 bolts are typically used.

In high-temperature environments, high-temperature alloy bolts or specially heat-treated high-strength bolts should be selected.

In low-temperature environments, brittle fracture must be prevented, so materials and strength grades with good low-temperature toughness should be chosen.

In corrosive environments, bolts made of corrosion-resistant materials should be selected based on the type and concentration of the corrosive medium.

If a connection requires frequent disassembly, bolts with moderate strength grades and good toughness should be selected.

If the installation is one-time and requires high clamping force, higher-strength bolts can be used, but tightening torque must be carefully controlled.

Bolt type and material also have an important influence on strength. The following are some common bolt types and materials:

Coarse threads have greater thread engagement height, strong wear resistance, and are less prone to thread stripping.

Fine threads have better self-locking performance and higher bolt strength, making them suitable for impact, vibration, and variable load conditions.

Low-carbon steel and carbon steel are the most widely used materials.

For bolts subjected to impact, vibration, and variable loads, alloy steel is commonly used.

Under special requirements, stainless steel, aluminum alloys, copper alloys, and titanium alloys may also be used.

When selecting and installing bolts, the following points should be noted:

The strength grades of bolts and nuts must be properly matched to prevent connection failure.

Generally, the strength grade of the nut should be slightly lower than that of the bolt.

For example, grade 8.8 bolts are typically matched with grade 8 nuts, while grade 10.9 bolts are matched with grade 10 nuts.

Common standards for high-strength bolts include ISO, GB, and DIN. These standards specify bolt dimensions, strength grades, and surface treatment requirements, providing a basis for bolt production, selection, and use.

When selecting high-strength bolts, products that comply with relevant standards should be chosen according to actual needs.

During bolt installation, tightening torque must be properly controlled to avoid bolt damage caused by excessive tightening.

At the same time, bolt and nut surfaces should be kept clean to prevent connection failure caused by contaminants.

Bolt strength grades are important indicators for evaluating the mechanical performance of bolts. By understanding bolt strength grades and their classification standards, we can better select and use bolts to ensure the safety and reliability of various mechanical and construction structures. In practical applications, bolt strength grades should be reasonably selected according to specific service conditions and load requirements, while also paying attention to bolt type, material, and installation points. In conclusion, although bolts are small, their importance cannot be overlooked. It is hoped that this article will help you better understand bolt strength grades and correctly apply this knowledge in practical work.