Electric valves are widely used in nuclear power plants; however, during long-term operation, they are exposed to harsh conditions—including high temperature, high pressure, and intense radiation—which contribute to a high rate of failures. This study investigates diagnostic technologies for assessing the key performance of in-service electric valves without the need for disassembly. The study introduces three typical failure modes of electric valves along with their corresponding diagnostic methods. In addition, a dedicated system for assessing the key performance of electric valves in nuclear power plants has been developed. The system monitors valve state parameters by acquiring electrical and mechanical signals and evaluates the operating health of the valve based on motor power, valve stem load, stroke characteristics, and the timing logic of opening and closing operations. This approach offers a reliable basis for fault diagnosis and condition-based health management of electric valves in nuclear power plants.

Valves are critical components in pipeline systems, responsible for regulating the flow rate, temperature, pressure, and direction of process media. They are often described as the 'throat' of fluid pipeline systems. Nuclear power plants contain a vast number of valves; a single unit typically has over 18,000 valves, of which around 900 are electrically actuated. During the service life of a nuclear power plant, valves are exposed to severe conditions—including high temperature, high pressure, and intense radiation—which greatly increase the risk of failure. Statistical data indicate that valve failures account for over 15% of all equipment failures in nuclear power plants. In particular, failures of safety-related valves can result in serious accidents, including radioactive leakage. The performance evaluation and fault diagnosis of electric valves primarily rely on monitoring their operational state parameters. Valve faults are identified by processing and extracting features from monitoring data, using electrical and mechanical diagnostics, as well as both online and offline diagnostic methods. Yang Ken et al. designed and developed a clamp-on thrust sensor for on-site monitoring of valve stem thrust in electric valves. Bai Bing et al. investigated the performance variations of AP1000 electric gate valves under both loaded and unloaded conditions by monitoring valve stem thrust and torque. Kim et al. estimated friction coefficients from valve stem thrust and torque measurements, allowing assessment of potential performance degradation during long-term operation. Granjon et al. analyzed mechanical fault indicators in electric valves through electrical signal monitoring, while Kang et al. assessed whether valve stem thrust met design load requirements by deriving motor output torque from current and voltage s ignals. Zhang et al. analyzed the power curves and characteristic operating points of electric valves by acquiring voltage, current, and switching signals. With the rising demand for electric valve diagnostics, especially in nuclear power applications, portable diagnostic equipment has received increasing attention. Ningsheng Wu developed a fault diagnosis module based on electrical signal acquisition, which calculates motor output torque from current and voltage measurements to evaluate operating characteristics and detect faults in electric valves under complex industrial conditions. Available information also suggests that Teledyne’s Quiklook diagnostic system can be applied to valve testing. In summary, existing diagnostic technologies for electric valves need to consider the unique service conditions of nuclear power plant valves. These technologies typically assess valve stress states by acquiring current and voltage signals and detecting faults through analysis of the signal characteristics. However, reports on portable diagnostic equipment are still limited. Therefore, this study systematically investigates key performance testing and diagnostic technologies for electric valves and presents the design and development of a portable diagnostic device for evaluating valve performance, offering a practical solution for health monitoring of industrial and nuclear power plant valves.

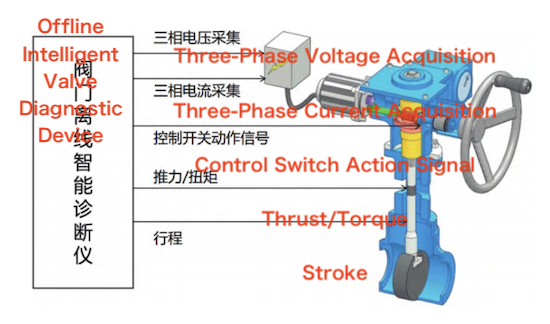

The objective of key performance testing and diagnostic technologies for electric valves is to install power, current, switching signal, strain, and displacement sensors on the valve without disassembly, as shown in Figure 1. By acquiring state parameters—including motor voltage, motor current, switching signal sequence, valve stem torque and thrust, and valve stroke—and performing the corresponding calculations and analyses, characteristic parameters for valve performance diagnosis, such as motor power, valve stem force, and stroke time, can be obtained. Based on the resulting monitoring curves and characteristic parameters, the key operational performance of the electric valve can be evaluated and diagnosed.

Offline Intelligent Valve Diagnostic Instrument

Three-phase voltage acquisition

Three-phase current acquisition

Opening/closing action signals

Force/Torque measurement

Stroke measurement

Figure 1. Schematic diagram of electric valve state parameter monitoring

During electric valve diagnostics, the acquired monitoring curves typically include thrust–time, torque–time, current–time, control switch signal–time, and stroke–time plots. During the opening and closing of an electric valve, the axial force on the valve stem—whether tensile or compressive—serves as a key indicator of valve performance. By analyzing the characteristic points on these curves and comparing them with the original design data, the valve's operational condition can be accurately assessed.

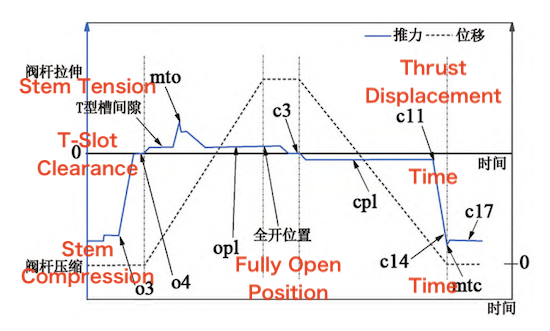

Figure 2 illustrates the thrust–displacement–time curve. The functions of the key characteristic points are explained below in conjunction with the stroke–time and thrust–time curves.

O3: The motor worm gear begins to engage with the rotating bushing, resulting in a transient hammering effect.

O4: After engagement, the worm gear drives the bushing to rotate, gradually releasing the compressive force on the valve stem until it reaches zero, marking the transition from compression to tension.

MTO: The tensile force generated by the motor overcomes the friction between the valve stem and the packing, as well as the friction between the valve disc and the valve seat. At this point, the valve disc begins to lift off the seat.

OPL: Operating load during the opening process, representing the tensile force acting on the valve stem under normal operating conditions.

OED: The valve reaches the fully open position, and valve motion ceases.

C3: During closing, the rotating bushing releases the tensile force in the valve stem until it decreases to zero, indicating the onset of compressive loading.

CPL: Operating load during the closing process, corresponding to the compressive force acting on the valve stem.

CLL: As the valve disc enters the valve chamber, the pressure differential across the disc increases, resulting in a gradual increase in stem compressive force.

C14: Activation of the torque switch; due to motor inertia, the compressive force on the valve stem continues to increase momentarily.

MTC: Maximum axial compressive force experienced by the valve stem.

C17: Axial compressive force sustained on the valve stem when the valve is fully closed.

Figure 2. Thrust–displacement–time curve of an electric valve

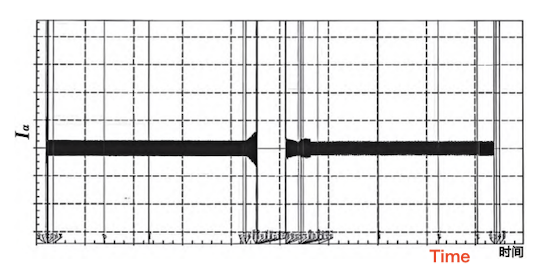

During electric valve diagnostics, the instantaneous three-phase motor current (or voltage) is measured in real time, as shown in Figure 3. Key electrical parameters, including starting current, average current, and effective current, are calculated. Based on these parameters, the motor output power and torque are analyzed to assess the operating condition of the electric actuator.

Figure 3. A-phase motor current–time curve

During diagnostic testing, action signals from the electric actuator—such as torque switch, limit switch, and bypass switch signals—are collected in real time. By correlating these signals with time and valve stroke data, the action logic and functional performance of each control switch can be evaluated.

Electric valves typically exhibit three major failure modes: internal leakage, operational failure, and external leakage. The associated failure mechanisms and diagnostic methods are summarized in Table 1. As shown in the table, the characteristic values of the key markers MTO, OPL, OED, CPL, and C17 on the monitoring curves serve as the primary parameters for failure identification and analysis. Other characteristic markers can serve as auxiliary indicators to support diagnostic evaluation.

|

Failure Mode |

Failure Mechanism |

Diagnostic Method |

Key Measurement Points |

|

Internal leakage |

Insufficient sealing force between valve disc and seat |

Assess whether valve stem thrust meets sealing requirements |

Compressive force at C17 |

|

Improper torque switch spring setting |

Assess torque switch trip timing |

C17 |

|

|

Inadequate closing stroke |

Check if stroke meets design specifications |

Displacement at C17 |

|

|

Delamination of sealing surface material on disc or seat |

Assess final closing load |

Compressive force at C17 |

|

|

Abnormal pull-out force |

Assess tensile force during opening |

Tensile force at MTO |

|

|

Adhesion or surface roughening of valve disc and seat |

Assess pull-out force |

Tensile force at MTO |

|

|

Failure to operate |

Valve stem bending or excessive wear |

Detect abnormal operating load during opening/closing |

Tensile/compressive force at OPL/CPL |

|

Insufficient output force due to actuator malfunction |

Evaluate actuator load and output capability |

Tensile/compressive force at OPL/CPL |

|

|

Insufficient opening stroke |

Check full open stroke |

Stroke at OED |

|

|

Insufficient motor output power |

Assess motor output power |

Motor power at OPL/CPL |

|

|

External leakage |

Packing failure, valve stem bending, or insufficient packing tightening torque |

Measure packing friction during opening/closing to evaluate leakage risk |

Tensile/compressive force at OPL/CPL |

|

Loosened packing gland follower reducing packing friction |

Monitor packing friction variation during operation to evaluate leakage risk |

Tensile/compressive force at OPL/CPL |

The nuclear power valve key performance diagnostic system, is a portable device designed to evaluate the performance of both electric and pneumatic valves. The system comprises a data acquisition unit, various sensors, and a host computer. The electric valve is connected to the data acquisition unit via current, voltage, strain, switching signal, and displacement sensors. The host computer communicates with the data acquisition unit over Ethernet or Wi-Fi. After launching the diagnostic software, the user creates and populates the valve information database, configures the sensor parameters, and selects the required test items. Upon receiving control commands from the host computer, the data acquisition unit sends electrical signals to control the valve’s operation. During valve actuation, the sensors continuously record variations in motor current, motor voltage, valve stem torque and thrust, switching signals, and valve stroke. These signals are transmitted to the host computer via the data acquisition unit. After noise filtering and signal processing, the data are displayed as real-time monitoring curves. Finally, characteristic parameters and diagnostic curves for evaluating valve operational performance are obtained through further calculations and analysis.

The host computer software measures and records key parameters, including motor current, motor voltage, valve stem torque and thrust, switching signal current, and valve displacement. These parameters are displayed graphically with time on the horizontal axis. A time slider at the bottom of the monitoring interface can be adjusted to zoom in on specific time intervals, allowing real-time observation of variations in the valve’s operating state. As shown in the figure, during the opening process, the torque required to overcome the maximum static friction reaches 710.46 ft·lb (MTO point), at which point the valve stem shows almost no displacement. Subsequently, the valve stem begins to move and is subjected to sliding friction, mainly from the packing, resulting in an operating load of 43.55 ft·lb (OPL). This value is close to the theoretical design range of 40–50 ft·lb, and both fall within the design requirements. During the closing process, the butterfly valve’s maximum seat load reaches 1000.08 ft·lb (CPL point), while the final load is 718.11 ft·lb (C17 point). This final load is close to the maximum torque at the MTO point, indicating that the valve’s closing and sealing performance meets the design requirements.

Other characteristic parameters for evaluating the key performance of electric valves are summarized in Table 2. As shown in the table, load-related parameters are the most critical indicators of electric valve performance and are closely linked to internal leakage, operational failure, and external leakage. The maximum and final loads provide the necessary sealing force between the valve disc and seat, while the average operating load serves as a key parameter for assessing whether the packing friction meets design specifications. Furthermore, the performance of the electric actuator can be assessed using the average and peak values of motor current, voltage, and power.

|

No. |

Characteristic Parameter (Valve Closing Process) |

No. |

Characteristic Parameter (Valve Opening Process) |

|

1 |

Maximum operating load |

14 |

Opening operating load |

|

2 |

Average operating load |

15 |

Maximum load after opening |

|

3 |

Control switch trip load |

16 |

Average opening load |

|

4 |

Final closing load |

17 |

Opening control switch trip load |

|

5 |

Closing stroke time |

18 |

Opening time |

|

6 |

Closing torque switch bypass time |

19 |

Opening stroke |

|

7 |

Motor peak current |

20 |

Indicator light response time |

|

8 |

Motor average operating current |

21 |

Opening force short-switch bypass time |

|

9 |

Motor maximum operating current |

22 |

Motor peak current |

|

10 |

Motor average voltage |

23 |

Motor average operating current |

|

11 |

Motor peak power |

24 |

Motor average voltage |

|

12 |

Motor average power |

25 |

Motor maximum operating current |

|

13 |

Motor maximum power |

— |

— |

Electric valves are widely used in the piping systems of nuclear power plants, primarily as electrically actuated components that play a crucial role in ensuring safe and reliable system operation. This study presents a key performance diagnostic technology for in-service electric valves without disassembly and introduces a dedicated diagnostic system for nuclear power plant valves. By monitoring valve state parameters and extracting key characteristic values, the three typical failure modes of electric valves—internal leakage, operational failure, and external leakage—can be effectively assessed. The developed nuclear power valve key performance diagnostic system enables real-time acquisition and monitoring of electric valve operating parameters and displays them as characteristic curves. Through further calculation and analysis, key performance parameters are obtained to assess whether the electric valve meets design and operational requirements. Future research will focus on developing intelligent fault diagnosis and automated generation of diagnostic reports. By integrating real-time monitoring data, historical diagnostic records, and factory health data, intelligent diagnosis and operation-and-maintenance strategies can be achieved using a combination of mechanism-based and data-driven fusion algorithms. This approach aims to address challenges such as difficult fault localization and high operation and maintenance costs, thereby enhancing the reliability and efficiency of nuclear power valve management.