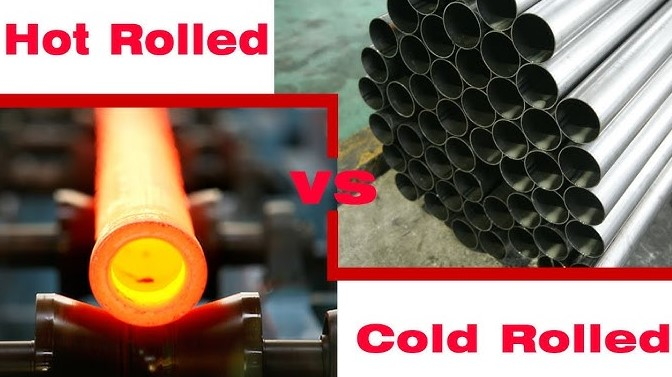

In modern industrial sectors, seamless steel pipes are an essential basic material and are widely used in construction, machinery manufacturing, petrochemical processing, aerospace, and many other industries. Among them, hot-rolled seamless steel pipes and cold-rolled seamless steel pipes are the two primary categories. Each features distinct manufacturing processes, performance characteristics, and application fields. This article provides an in-depth comparison of these two types of seamless steel pipes to help you make a more informed material selection.

Hot-rolled seamless steel pipes are a classic type of seamless pipe. Thanks to their efficient production process and broad applicability, they play a vital role in industrial applications. The hot-rolling process enables large-scale production while meeting diverse engineering requirements, making these pipes stand out among various materials.

The manufacturing process of hot-rolled seamless steel pipes is relatively complex and mainly includes the following key steps:

- Heating: The round billet is heated to a specified temperature until it reaches a plastic state, facilitating subsequent processing.

- Piercing: The heated billet is pierced using a piercing mill to form a hollow shell.

- Rolling: Rolling mills are used to roll the hollow shell to achieve the required shape and dimensions.

- End Cutting: Excess material at both ends of the pipe is removed to ensure proper length and appearance quality.

- Cooling: The rolled pipe is cooled to room temperature.

- Post-Processing: This includes straightening, hydrostatic testing (or non-destructive testing), marking, and warehousing to ensure the pipe meets quality standards.

The main performance characteristics of hot-rolled seamless steel pipes include:

- Relatively low dimensional accuracy: Since processing is carried out at high temperatures, shrinkage during cooling can lead to uneven wall thickness and relatively large deviations in diameter and wall thickness.

- Lower tensile strength and yield strength: Due to the relatively simple hot-rolling process, the microstructure and properties are less compact and stable, resulting in lower tensile and yield strength.

- Inferior surface quality: Oxide scale forms during hot rolling, leading to surface defects and relatively lower corrosion resistance.

- Lower cost: With a simpler manufacturing process, hot-rolled seamless steel pipes have lower production costs and are therefore more economical.

Owing to their cost advantage and satisfactory mechanical properties, hot-rolled seamless steel pipes are widely used in:

- Construction industry: For structural supports, bridges, and other load-bearing components.

- Machinery manufacturing: For automotive chassis, exhaust systems, hydraulic cylinders, and mechanical parts.

- Oil and gas industry: Used as oil well casing, oil and gas pipelines, and key materials for petroleum equipment. Their high strength, wear resistance, and impact resistance meet the stringent requirements of oil and gas extraction and transportation.

Cold-rolled seamless steel pipes are considered high-end seamless pipe products. With their high precision, high strength, and excellent surface quality, they have become the preferred choice for many demanding industrial applications. The refined cold-rolling process allows these pipes to achieve outstanding dimensional accuracy, surface finish, and mechanical performance, making them indispensable in critical fields such as machinery manufacturing, petrochemicals, and aerospace.

The manufacturing process of cold-rolled seamless steel pipes places greater emphasis on detail and precision and mainly includes the following steps:

- Heating and Piercing: Similar to hot-rolled pipes, the round billet is first heated and pierced to form a hollow shell.

- Pickling, Phosphating, Saponification, and Lubrication: The hollow shell is pickled to remove oxide scale; phosphating improves corrosion resistance; saponification and lubrication provide favorable surface conditions for cold rolling.

- Cold Rolling: The hollow shell undergoes multi-pass rolling on a cold-rolling mill to achieve the required dimensions and precision.

- Post-Processing: This includes heat treatment, straightening, hydrostatic testing (or non-destructive testing), marking, and warehousing to ensure compliance with high-precision requirements.

The key performance characteristics of cold-rolled seamless steel pipes include:

- High dimensional accuracy: Plastic deformation occurs at relatively low temperatures, and after multiple precise processes, wall thickness is uniform with minimal deviation in diameter and thickness. For standard products, outer diameter tolerances can be controlled within ±0.05 mm and wall thickness tolerances within ±0.1 mm. In special industries, requirements can even reach micrometer-level precision, such as for aerospace engine components and medical devices.

- High tensile strength and yield strength: Due to multiple processing steps, the microstructure is denser and more stable, resulting in higher tensile and yield strength. Cold-rolled pipes can achieve yield strengths above 500 MPa, while conventional hot-rolled products typically range from 300 to 400 MPa.

- Excellent surface quality: Both inner and outer surfaces are smooth, free of oxide scale, and exhibit good corrosion resistance. Surface roughness data show that cold-rolled pipes can achieve Ra values below 0.8 μm—more than two grades better than hot-rolled products.

- Higher cost: The complex manufacturing process leads to higher production costs and, consequently, higher prices.

Due to their high precision, high strength, and good corrosion resistance, cold-rolled seamless steel pipes are widely used in:

- Petrochemical industry: For high-pressure reactors, heat exchangers, and other equipment operating under high temperature, high pressure, and corrosive conditions.

- Pressure vessel industry: For manufacturing high-pressure vessels and boilers, ensuring safe and reliable operation.

- Machinery manufacturing: For key components in hydraulic and pneumatic systems, ensuring high precision and reliability.

- Aerospace industry: For critical components of aircraft and rockets, such as engine parts and wing structures, meeting extremely stringent material requirements.

- Automotive industry: For transmission shafts, steering shafts, and other critical components to enhance vehicle performance and safety.

- Decorative stainless steel pipes and food machinery conveying pipelines: Their superior surface quality makes cold-rolled seamless steel pipes irreplaceable in these applications.

- Dimensional Accuracy: Hot-rolled seamless steel pipes have relatively low dimensional accuracy, with uneven wall thickness and larger deviations in diameter and thickness. In contrast, cold-rolled seamless steel pipes offer much higher dimensional accuracy, with uniform wall thickness and minimal deviation. Standard products can achieve outer diameter tolerances within ±0.05 mm and wall thickness tolerances within ±0.1 mm, while special applications may require micrometer-level precision.

- Strength and Hardness: Hot-rolled seamless steel pipes exhibit lower tensile and yield strength, whereas cold-rolled pipes offer significantly higher strength. Cold-rolled pipes can reach yield strengths above 500 MPa, compared to 300–400 MPa for typical hot-rolled products. This strength advantage is particularly valuable in load-bearing structures such as crane booms, although subsequent annealing may be required to mitigate brittleness caused by work hardening.

- Surface Quality: Hot-rolled seamless steel pipes have surface defects and oxide scale, resulting in lower corrosion resistance. Cold-rolled pipes, on the other hand, feature smooth surfaces without oxide scale and offer superior corrosion resistance. Surface roughness measurements indicate that cold-rolled pipes can achieve Ra values below 0.8 μm, more than two grades better than hot-rolled products.

- Price: Hot-rolled seamless steel pipes are more affordable due to their simpler manufacturing process, while cold-rolled seamless steel pipes are more expensive because of their complex processing and higher production costs.

- Suitable Applications for Hot-Rolled Seamless Steel Pipes: Thanks to their cost advantage and reliable mechanical performance, hot-rolled seamless steel pipes are suitable for applications where dimensional accuracy is not critical and cost sensitivity is high. Typical fields include construction, machinery manufacturing, and the oil and gas industry. They are commonly used for automotive chassis, exhaust systems, hydraulic cylinders, and mechanical components, offering high strength, wear resistance, and impact resistance. In the oil and gas sector, they are widely used for oil well casing, pipelines, and petroleum equipment.

- Suitable Applications for Cold-Rolled Seamless Steel Pipes: With high precision, high strength, and excellent corrosion resistance, cold-rolled seamless steel pipes are ideal for applications with stringent dimensional and performance requirements. These include petrochemicals, pressure vessels, machinery manufacturing, aerospace, and automotive industries. In petrochemicals, they are used for high-pressure reactors and heat exchangers; in pressure vessel manufacturing, for high-pressure containers and boilers; in machinery manufacturing, for hydraulic and pneumatic system components. They are also critical in aerospace applications for aircraft and rocket components, and in automotive manufacturing for transmission and steering shafts.

Hot-rolled and cold-rolled seamless steel pipes each have unique manufacturing processes, performance characteristics, and application fields. Hot-rolled seamless steel pipes, with their relatively simple production process and lower cost, are widely used in construction, machinery manufacturing, and the oil and gas industry. Cold-rolled seamless steel pipes, characterized by high precision, high strength, and excellent corrosion resistance, are better suited for demanding applications in petrochemicals, pressure vessels, machinery manufacturing, aerospace, and automotive industries.

When selecting seamless steel pipes, it is essential to consider application requirements and budget, taking into account factors such as dimensional accuracy, strength, surface quality, and cost. By doing so, you can ensure the most appropriate material choice to meet engineering and manufacturing needs.

Through this detailed discussion, we hope you now have a clearer understanding of the differences between hot-rolled and cold-rolled seamless steel pipes. In practical applications, selecting the right type of seamless steel pipe is crucial for ensuring project quality and improving production efficiency. We hope this article serves as a valuable reference and helps you make well-informed decisions.